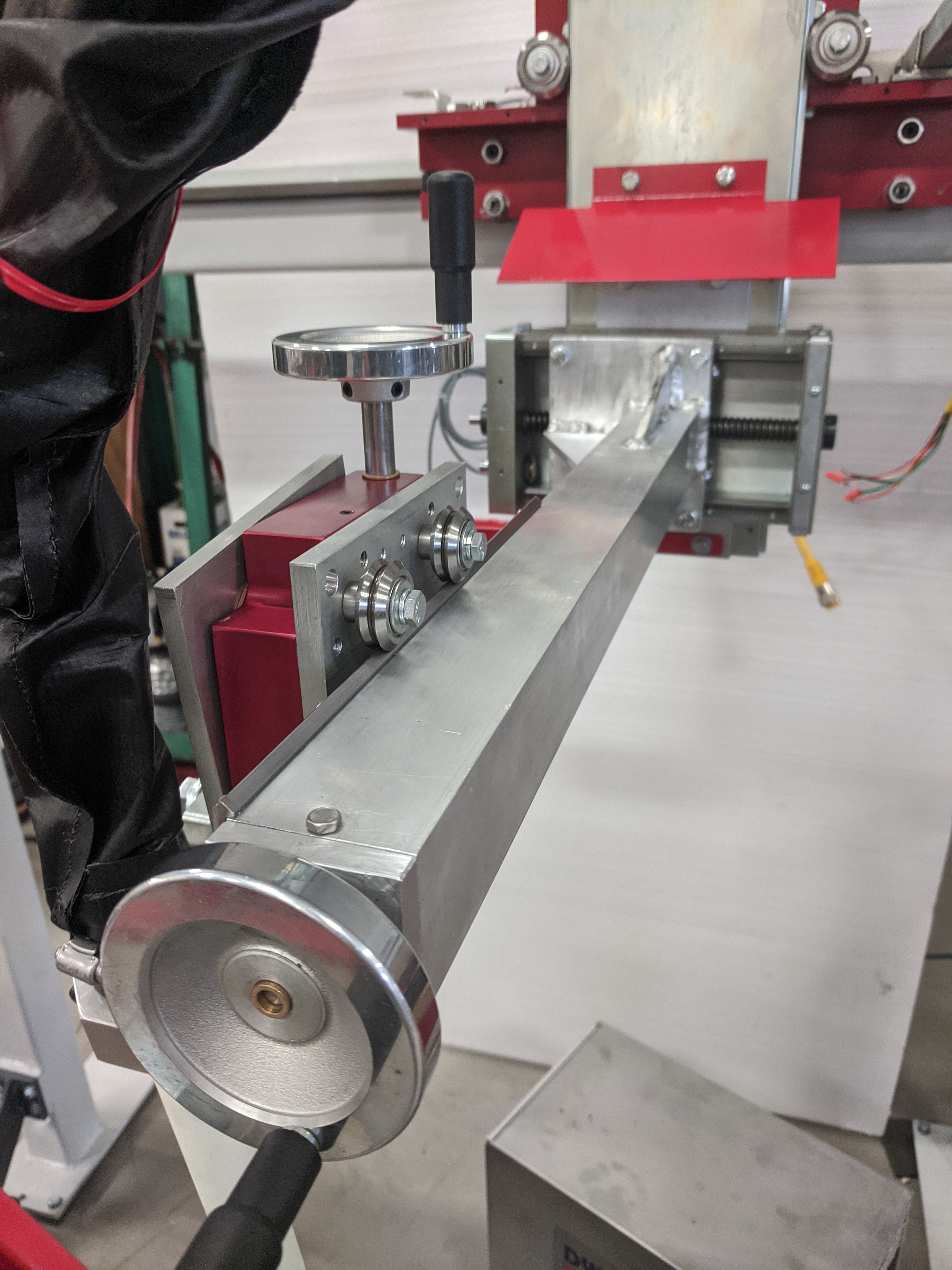

If you can’t stand the heat, get out of the kitchen. Or in this case, if your products can’t withstand the heat, step aside as this is where Bishop-Wisecarver excels. Just ask our long-time customer, Mavrix Welding Automation of Wisconsin. Mavrix designs and builds standard and custom machines for special purpose welding and fabrication. Their customers include agriculture, oil & gas, recycling, and steel manufacturing industries that need robust and durable machines built to last.

Products

-

Posted: December 29, 2021||Read more »

-

Posted: July 28, 2021||Read more »These competitor products fail to perform to the same levels as DualVee®, and their product limitations not only hinder machine reliability, but also increase the total cost of ownership (TCO) for customers.

-

Read more »Loop. Shag. Pile. Plush. Deciding on the type of carpet and the color, and then researching how to get out wine stains and muddy paw prints, is the extent of knowledge most of us have around floor coverings.

-

Read more »No matter your industry, when it comes to designing cutting systems, the need for equipment that can last multiple years, through multiple cycles, while withstanding harsh environments is a must. From food to shavings and anything in between, cutting means debris. So asking - and answering - the right questions in advance can help successfully influence the design of any automation project.

-

Read more »Industry 4.0 is a much discussed topic in the manufacturing world as it has the ability to create faster, more efficient and flexible processes that produce higher-quality goods at lower costs. But while those are all great benefits, the new technology doesn’t work without a skilled workforce. The skills gap in the manufacturing industry is already extensive and figuring out how to get newly skilled workers, while training current workers, was the focus of last week’s Automate Forward panel discussion “Building an Industry 4.0 Workforce for the Future”.

-

Read more »As Bishop-Wisecarver continues celebrating its 70th Anniversary this year, it is the ideal timing to achieve Certified Evergreen® status from the Tugboat Institute®. This certification highlights the company’s continued commitment and vision to build and scale as a privately owned business for generations to come.

-

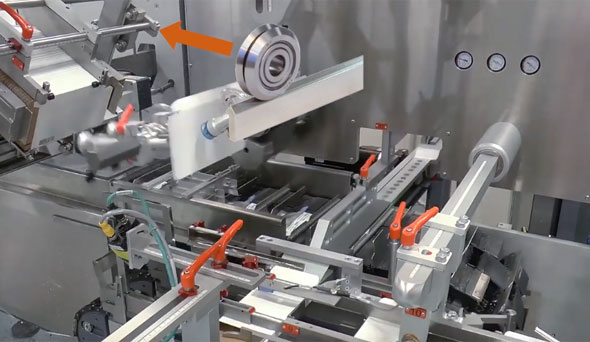

Posted: February 02, 2021||Read more »Recently, our experienced design engineers used their ingenuity and deep product knowledge to create a custom hybrid LoProⓇ/UtiliTrakⓇ actuator for the DJS Systems Trim Press Automation (TPA) solution. The new hybrid actuator design significantly increases the overall integrity of the overhead actuator axis, with reduced complexity due to fewer component parts. It also provides 421% more axial capacity and 300% more pitch movement capacity.

-

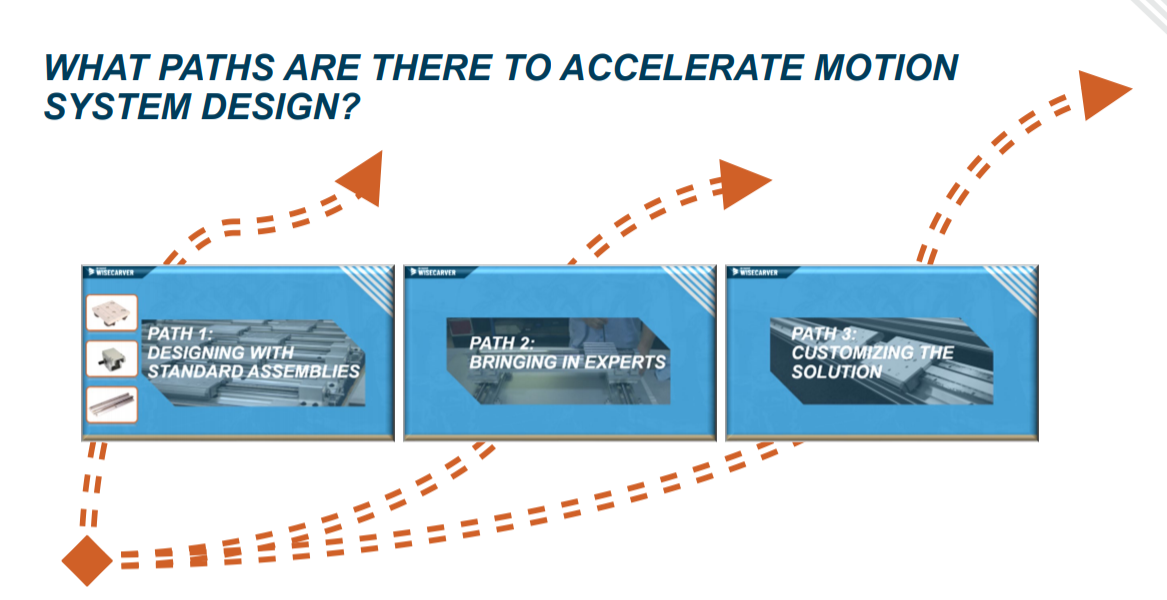

Read more »So, anything that can help speed up the time-consuming, complex process around designing and developing automated equipment is worth learning about. Check out our recent webinar on 3 Accelerators for Motion System Design to discover the 3 paths that will help minimize project complexity and align solutions to your project requirements.

-

Read more »Bishop-Wisecarver’s MinVee® Miniature Linear Guides provide all the benefits of the patented DualVee products, but with a compact carriage assembly and smaller double edged track. With axial load capacities up to 121 pounds and speeds up to 5 m/s It is an ideal motion solution for customer applications including medical, laboratories, packaging and semiconductor.

-

Read more »There are more adjectives to describe Bishop-Wisecarver’s DualVee Guide Wheel technology, but you get the point. The patented vee guide wheels were designed by founder Bud Wisecarver in 1968 and the company’s signature product has been helping customers with quiet, low friction motion in even the most extreme conditions for more than 50 years.