7th Axis Solutions

Add extremely durable 7th axes and robot transfer units (RTUs) of any length to your automation project.

Robot positioning systems (7th axis or Robot Transfer Units) provide flexibility in manufacturing and industrial spaces. Both traditional and collaborative robots can benefit from Bishop-Wisecarver’s 7th axis motion solutions, regardless of their size. Our solutions make it easier than ever to extend your automation capabilities!

Our robot transfer systems are expertly designed to perform critical operations - in even the harshest environments and most extreme applications. Unexpected downtime can spell disaster in terms of liability, productivity, and revenue. That is why Bishop-Wisecarver delivers reliable, long-lasting RTUs and 7th axis systems.

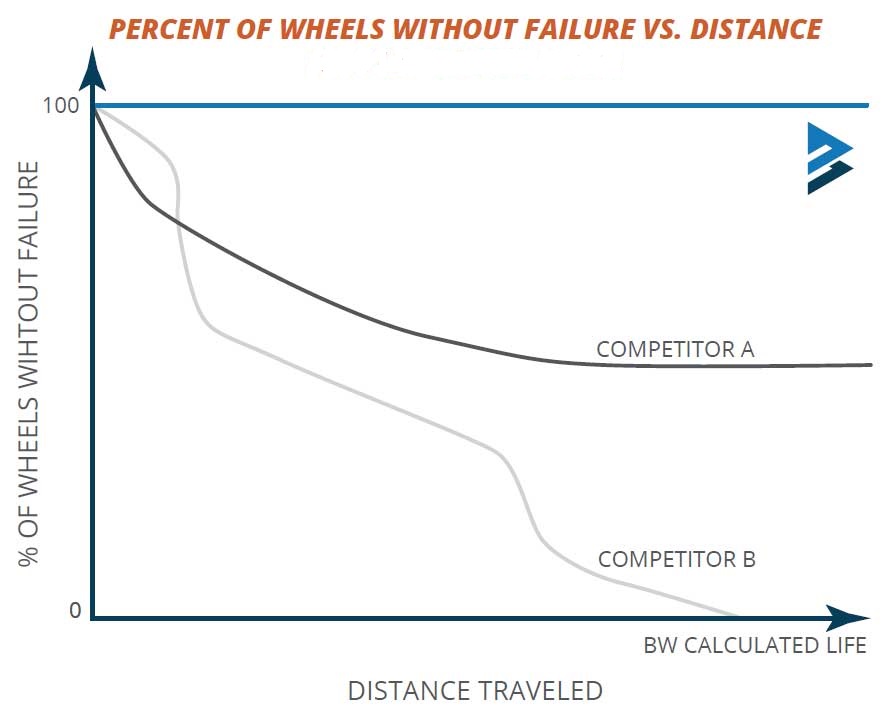

These durable RTUs are built on DualVee Motion Technology® for self-cleaning guidance, low maintenance, and unparalleled dependability. Many solutions that run on DualVee guide wheels require no maintenance over the planned life of the machine. This ability to excel in debris-prone and critical applications makes Bishop-Wisecarver's solutions ideal for drilling, welding, painting, and more.

Contact our Expert Application Engineers for help specifying and customizing your system!

Robot Transfer Units Built on DualVee Motion Technology

LoPro® RTU: Light and Medium Capacity

Two sizes of ready-to-mount, belt-driven RTUs capable of horizontal or inverted installation.

Includes:

- Belt-driven actuator with single wheel plate (RTU-L) or double wheel plate (RTU-M)

- Mounting plate with hole pattern matched to your robot

- 5:1 planetary gearbox as standard

- Motor mount matched to your drive motor of choice

- Cable carrier

- Homing sensor

DualVee® RTU: Heavy Capacity

Durable rack-driven RTUs capable of high capacity loading (11.7 klbf or 52.4 kN).

Includes:

-

Robust rack drive with automated lubricator

-

Mounting plate with hole pattern matched to your robot

-

20:1 planetary gearbox as standard

-

Motor mount matched to your drive motor of choice

-

Cable carrier and tray

-

Homing sensor and travel bumpers

LoPro & UtiliTrak - Manufacturing - Collaborative Robotics

Automated machine tending between two CNC lathes. A LoPro® actuator acts as the 7th axis, while UtiliTrak® guides the part caddy.

HepcoMotion Heavy Duty Robot Transfer Units

HepcoMotion HDS2 Heavy Duty Slide System

- Long life systems, often requiring zero maintenance

- 4 vee guide wheels can handle 68 kN (over 15,200 lbf)

- Available as assembled systems (reducing design and installation time) or in component form

- Vee guide wheels provide self-cleaning action for debris resistance in industrial automation settings

- Available in corrosion resistant stainless steel

- Unlimited transfer lengths (4 m track segments are easily butt-joinable and aligned in parallel without high precision requirements)

- High driving force, low backlash rack drives (spur or helical)

- Automatic lubrication options for pinion/rack and optionally for wheels/track; system can run dry (without lubrication) if required

GRS Gear Robotic System / Lucas Robotic System

The principle is based on a patented "switch" system that allows our rigid axes (tracks or Cartesian robots) to make orientation changes from 0 to 360° in all axes.

HepcoMotion MHD Heavy Duty Track Guide

- Extreme load capacities can handle high offset and overhanging loads and provide long life with zero maintenance in most applications

- 4 roller bearing blocks running on flat tracks can handle 132 kN (over 29,600 lbf)

- Unlimited transfer lengths (flat track segments are easily butt-joinable and aligned in parallel without high precision requirements)

- High driving force, low backlash rack drives (spur or helical)

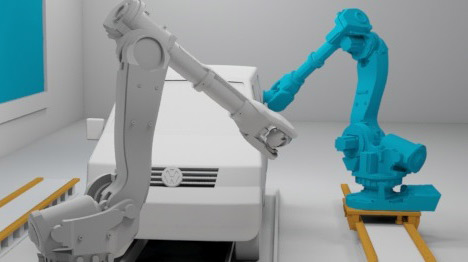

Example of MHD systems in 7th axis automotive application.

Heavy Duty Linear Guides: Robotic Arm

Increase productivity in a variety of industries, including aerospace, automotive, robotics, transfer system, welding system and material handling—anywhere high offset loads are seen in heavy automation applications, where durability and long life is required.

Support and transfer heavy industrial robots or those carrying high moment loads with the reliable and versatile HDS2 and MHD families of products. Bishop-Wisecarver is proud to be the exclusive North American distributor of HepcoMotion products since 1984.

Why Bishop-Wisecarver?

Bishop-Wisecarver specializes in motion solutions that are expertly designed and delivered to perform, from a company you can trust.

Our solutions deliver maximum environmental and debris resistance. This ability to excel in harsh and extreme conditions is especially critical for drilling, welding, painting, etc.

Additionally, BW systems are specifically design by our motion experts to minimize your installation effort and maintenance costs. Many solutions require no maintenance over the planned life of the machine. (Click here to read more about the total cost of ownership advantage of our products.)

We don’t just deliver quality products; we deliver a Signature Experience™ to our customers. Bishop-Wisecarver’s expert application engineers can help you select the complete 7th axis system solution that is right for you, including motors and controls. Our team can also partner with you to design a fully customized system that meets your application requirements.