Food Processing

A Cut Above the Rest

Bishop-Wisecarver has created innovative solutions for tough mechanical engineering challenges. Our high quality linear, rotary, and track circuit systems are proven to excel in food processing automation, and our self-cleaning vee guide wheel technology wipes away dust and debris. Additionally, Bishop-Wisecarver’s expert engineers help design custom motion systems that provide differentiating features in your equipment.

DURABLE AGAINST DEBRIS

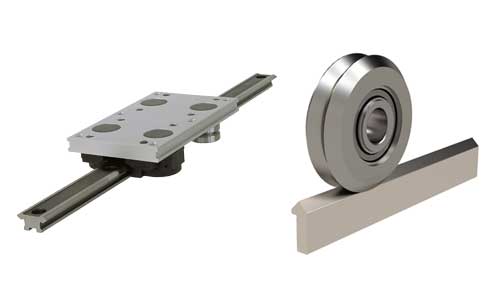

At the core of our systems and actuators is DualVee Motion Technology®. As vee wheels run on their matching track, the angled profiles wipe debris away, preventing buildup and motion system failure. DualVee Motion Technology® CLEANS ITSELF and wipes away food scraps and other debris – it is especially well-suited for food processing operations and those requiring reliable uptime:

- Harsh chemicals

- Durable goods

- Plastics and foam

- FDA approved grease

- Food product (dry, wet, or sticky)

- Fibers, dust, dirt, and more.

Fully sealed motion systems, protective covers, and sealed/shielded components add even more layers of protection as needed!

DualVee®, UtiliTrak®, and HepcoMotion® GV3 are smooth-running and highly versatile guidance components that every packaging machine designer should have in their toolbelt.

Patented washdown guide wheels are made of all stainless steel construction, FDA approved grease and AISI type 440C stainless steel balls and races with dual seals for added protection from high pressure liquids and debris.

HepcoMotion® PRT2 disks and large open center rings provide rotary motion for orbital wrapping, slewing in bottling operations, and more.

Stainless steel precision ring and track systems include a wide range of single/double edged rings, slides and segments. This low-friction,

debris- tolerant system offers many sizes, track shapes and customizations.

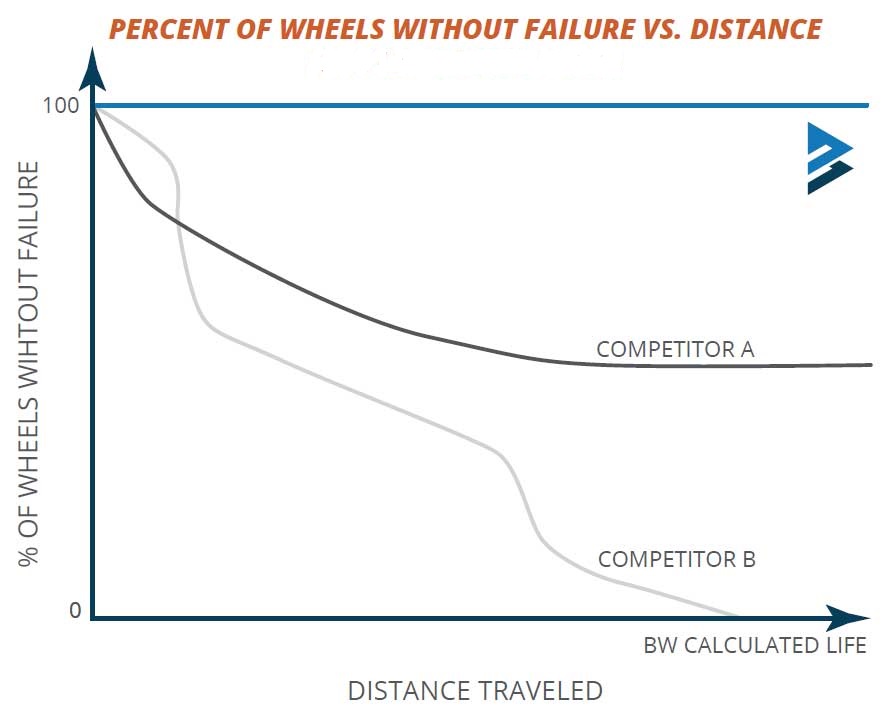

Long-Lasting Motion Systems

Importantly, BW systems inherently provide LONG LIFE with LOW MAINTENANCE. See how our DualVee® wheel and track systems outlast and outperform the competition in THIS WHITEPAPER:

ENHANCED THROUGHPUT

- Speeds up to 18 ft/s (5.5 m/s) and accelerations up to 5 g’s enable high throughput.

- Durability and low maintenance can reduce shutdown time for end users and increase profit.

- For flexible machines that must deliver quick changeover times, DualVee Motion Technology® enables smooth-running adjustment and fast assembly swapping.

- Design your optimal motion path for both speed and footprint by using BW linear, rotary, or complex curved systems.

EXCEL IN THE TOUGHEST ENVIRONMENTS

In addition to high debris and high throughput applications, Bishop-Wisecarver provides solutions for your toughest motion challenges.

- Hygienic and food grade: Stainless steel construction + H1 grease OR without lubrication

- High load and moment capacity options to move entire packaging machine subassemblies

- Extremely smooth motion over any length – well-suited for printing, scanning, and more

GET DESIGNING FAST

Our expert Application Engineers can help you design a motion system that meets all your application requirements - using standard or fully custom solutions.

Check out our product selector to learn more about the BW products that fit your needs or our CAD downloads to see our products in your design!

If you’re designing a gantry or multi-axis system visit our gantry page to learn more.

APPLICATION EXAMPLES

Melon Cutting Automation

Our customer required a solution to streamline and automate their melon cutting, and opted to use a reciprocating guillotine. The blade had to travel linearly a total of 180,000 inches per day in high-cycle operation. Any components used to guide this motion must be food grade, non-corroding, and suitable for a washdown environment.

PRODUCT USED: Stainless Steel DualVee Wheels and Track, Washdown Series Guide Wheel

Download PDF of Food Processing Application Solutions

Download PDF of Food Processing Industry Segment