Transfer

Whether moving an industrial robot across the factory floor or transferring electronic assemblies at high speeds…

Bishop-Wisecarver provides the smooth and dependable guidance and automation technology to get your equipment moving.

- Laboratory/medical industry OEMs rely on Bishop-Wisecarver to deliver smooth motion and corrosion resistance.

- Our guides and actuators are critical to the durability of automated farming and precision agriculture equipment.

- In entertainment, BW technology creates smooth and quiet motion so that nothing takes away from the production .

Bishop-Wisecarver products are the right fit for transferring tools and product in a variety of automation industries.

SMOOTH MOTION, LONG LENGTHS, & HIGH SPEEDS

At the core of our systems and actuators is DualVee Motion Technology®.

Our vee track comes in base lengths up to 22 ft (~6.7 m) and can be joined end-to-end (without costly precision alignment and machining) to create long transfer systems.

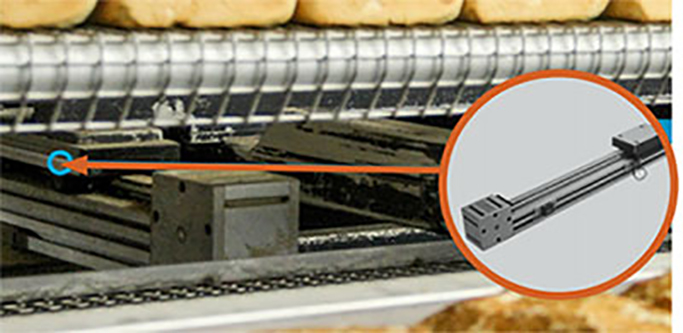

Additionally, as vee wheels run on their matching track, the angled profiles wipe any debris out of the way. This self-cleaning action keeps the motion extremely smooth and prevents buildups that could lead to motion system failure.

Speeds up to 18 ft/s (5.5 m/s) and accelerations up to 5 g’s enable high throughput transfer processes.

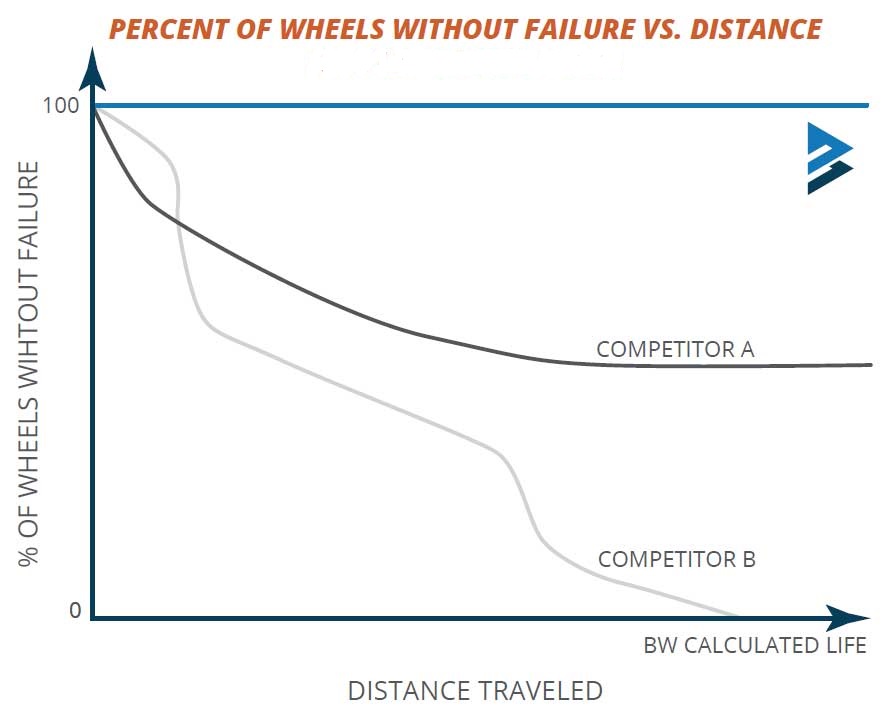

Long-Lasting Motion Systems

Importantly, BW systems inherently provide LONG LIFE with LOW MAINTENANCE. See how our DualVee® wheel and track systems outlast and outperform the competition in THIS WHITEPAPER:

CORROSION RESISTANCE AND DURABILITY IN EXTREME ENVIRONMENTS

Bishop-Wisecarver provides solutions for your toughest motion challenges.

- Corrosion resistant options – complete solutions with stainless steel, anodized aluminum, and polymer-overmolded components

- Options for High temperatures (up to 500 °F / 260 °C) and low temperatures (down to -94 °F / -70 °F)

- Vacuum-grade wheels ideal for lab, semiconductor, etc.

- Patented double-sealed wheel options to protect against washdowns

- High load and moment capacity options to move entire machine subassemblies and transfer robots

Check out our product selector to learn more about the BW products that fit your needs or our CAD downloads to see our products in your design!

DESIGN THE PATH YOU NEED

Design your optimal motion path for both speed and footprint by using BW linear, rotary, or complex curved systems.

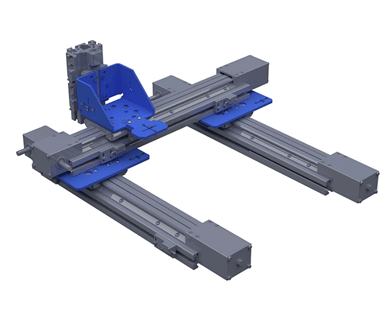

Take the guesswork out of creating a gantry or multi-axis inspection system – simply connect LoPro® Linear Actuators with a Gantry Kit.

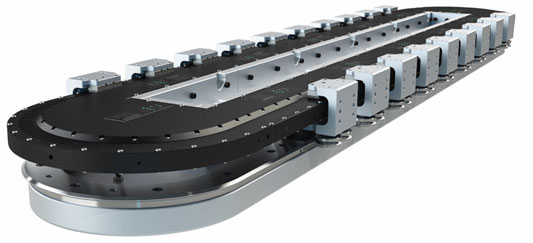

Designing rotary tables, long transfer circuits, and indexed stations is easy with HepcoMotion® Precision Ring and Track and Driven Track Systems.

Vee guide technology can even combine with linear motors to offer highly versatile, independently driven carriage transfer at high speeds.

|

Bishop-Wisecarver is proud to be the exclusive North American distributor of HepcoMotion® products since 1984. |

GET THE RIGHT SOLUTION FOR YOUR TRANSFER APPLICATION

Our expert Application Engineers can help you design a motion system that meets all your application requirements - using standard or fully custom solutions.

Leveraging 70 years of experience, Bishop-Wisecarver has earned the reputation for providing unmatched service and engineering support for every stage of your design cycle.

Bishop-Wisecarver is a trusted and reliable partner for everything from standard catalog motion components to custom integrated motion and control systems. Our world-class engineering support and custom manufacturing capabilities offer unsurpassed design flexibility.

Complex Assemblies

- Electro-mechanical assembly

- Supply chain & assembly services

- Purchase order consolidation

- Vendor management

- Kitting

Motion Products

- Linear guide bearings

- Linear actuators & motion stages

- Rotary & curvilinear motion guides

- Multi-axis actuated systems

- Automated motion systems

Automation & Integration

- Mechanical motion system design

- Electronic controls engineering

- Software & motion system integration

- Motion control system analysis

Production Support

- Profile extrusion design & finishing

- CNC milling/turning, grinding

- Fabrication, prototypes, production

- Finish coating, anodizing, painting

APPLICATION EXAMPLES

Packaging and Assembly

Bishop-Wisecarver HepcoMotion DTS2 High Speed Track System from Bishop-Wisecarver has been developed for high-speed applications. The use of a scroll drive allows rapid indexing to be achieved with superior positional accuracy.

Benchtop Immunoanalyzer

Operating 24/7, 364 days of the year, this is a high duty system requiring a low maintenance, reliable solution. For example, actuators must continuously load the 200°C oven, pushing loaves in every 30 seconds, 24 hours a day.

PRODUCT USED: DLS

Cosmetic & Personal Care Packaging

Machine runs continuously, shutting product from one conveyor to the ones above it. The bucket is raise and lowered through a synchronized toothed belt system attached to wheel plates on either side of the machine

PRODUCT USED: DualVee

Robot Transfer System

Transferring a 2 ton robot from a centralized station to a remote track by first rotating the holding station up to 360 degrees and lining up with a track introduces a number of technical challenges.

PRODUCT USED: HDS2

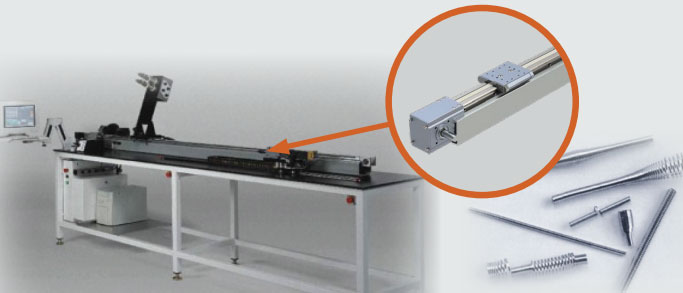

Coil-winding Automation

The medical industry was in need of a coil winder that could mass produce wound wire products yet, at the same time, meet the demand for extremely high-quality coils. These coils are used in various applications.

PRODUCT USED: LoPro

Download PDF of Transfer Application Solutions