HepcoMotion HDS2 – Heavy Duty Slide

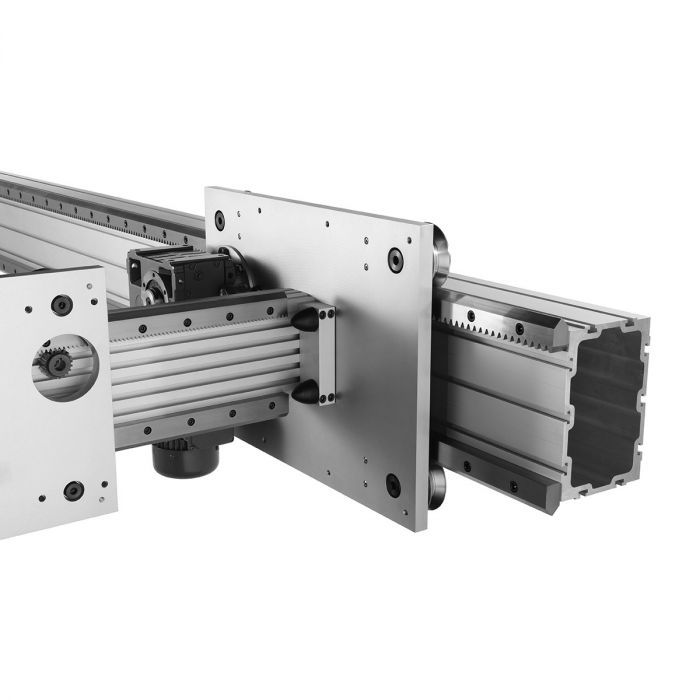

The HDS2 Heavy Duty Slide System line adds assembled carriages, two new sizes of construction beam, and a host of improved features to the proven HDS product line. Three new larger bearing sizes up to 150mm provide even higher load capacity (up to 50kN each). The expanded line also includes a new larger size 33 single edge V slide and flat tracks, as well as stainless steel or corrosion resistant component options. The advanced HDS2 system provides the flexibility for many sizes and types of heavy duty components to be interchanged to achieve a comprehensive combination of space and performance possibilities.

Chat with us to learn more about this product.

SKU

HDS2

Product Details

- Product Info

- Success Stories

- Videos

- Faqs

- Reviews

Units may be purchased assembled for quick installation, or as individual components for custom designs. V slides and flat tracks come in two grades; commercial for lower cost, or precision ground for higher accuracy applications. Gear racks can be added to single edge V slides and narrow flat tracks for linear actuation. Back plates offer another option for mounting V slides and flat tracks on a stable frame without the height of a construction beam. Bearing assemblies come in V slide bearings, track roller bearings, and bearing blocks to meet load and performance needs. Carriage plates are machined to customers' specifications from either steel or aluminum according to specific application needs.

Assembled Systems

HDS systems can be shipped as assembled units ready for installation. Mounting options include back plates and construction beam for V slides and flat tracks. Specify which guide type is required in each location, and the corresponding bearings desired. Additional accessories include gear racks and cap wipers, which increase the assembled unit's versatility and life, respectively.

V Slides and Flat Tracks

V slides and flat tracks are made from bearing quality carbon steel and hardened on wearing surfaces. The balance of the material is left in the annealed state to allow for additional machining. All V slides and flat tracks are available as a precision ground grade or as a commercial grade. The commercial grade is accurate enough for most applications, and is etched to allow for greater retention of lubrication along bearing contact surfaces. V slides are available as double edge or single edge. The single edge V slide can have a gear rack added. Flat tracks come in wide flat track and narrow flat track formats. Narrow flat tracks, like single edge V slides, can have a gear rack added.

Back Plates

Back plates allow for easy mounting of V slides and flat tracks, and may be used to directly mount to the customer's base, or to a construction beam. Back plates may be aligned using dowel pins or jacking screws. All back plates are made to tightly controlled tolerances from high strength aluminum alloy extrusion.

Bearing Assemblies

Depending on the carriage configuration, bearing assemblies can be purchased as through-hole fixing type (TH) or blind hole fixing type (BH). Through-hole fixing type bearings feature V slide bearings and track roller bearings in wide and narrow formats. Blind hole fixing type bearing assemblies allow the selection of the same bearing types as do through-hole fixing type bearings, but do not require through holes in the carriage. Neoprene seals are optional on any bearing type for additional protection against small particulates and liquids.

* When used with precision ground slides and tracks and properly lubricated.

Data Sheets

Beam Deflection Calculations

Download Now

Bearing Blocks

Download Now

Fixing of Slides and Bearing Elements

Download Now

Load Life Calculations

Download Now

Matched Systems

Download Now

Cap Wipers

Cap wipers provide optimal performance of systems by properly

lubricating the interface between the V slide and V bearing. Cap wipers

provide a grease reservoir for continuous lubrication during system

life.

Construction Beam

Extruded aluminum alloy construction beams enable slides and flat tracks

to be factory assemled directly to the corner faces of the beam or to

be mounted at the many T-slot positions in conjunction with back plates

and T-nuts. Construction beams are available in three sizes; HB33, HB25,

and HB25C, which has been designed to accommodate a screw drive.

T-Nuts, Pinions, and Carriage Plates

T-nuts, pinions, and assembled carriage units all add value to the HDS2

system by providing quick and easy means of attachment, actuation, and

customization, respectively. T-nuts come in flush T-nut style, location

T-nut style, and adjustment T-nut style to meet different requirements

when mounting to the construction beam. Pinions are available as bored

pinion and shaft pinion for mounting versatility.

Assembled carriages for all sizes of bearing are available to fit all

sizes of beam incorporating corner mounted slides. Carriages are also

available to fit double edge slides. Carriages are supplied with through

hole fixing bearings to facilitate direct removal from the slide. Cap

wipers and lubricators are available as options.

Bearing Assembly Technical Data

Bearing Element Type

Maximum Load Capacities

Axial Load LA

Radial Load LR

V Bearings THJR64 & BHJR64

2.5kN

8kN

V Bearings THJR95 & BHJR95

7kN

20kN

V Bearings THJR120/128 & BHJR120/128

10kN

30kN

V Bearings THJR150 & BHJR/150

17kN

50kN

Track Rollers THRR58 & BHRR58

0kN

10kN

Track Rollers THRR89 & BHRR89

0kN

20kN

Track Rollers THRR122 & BHRR122

0kN

30kN

Track Rollers THRR144 & BHRR144

0kN

80kN

Narrow Track Rollers THRN58 & BHRN58

0kN

5kN

GLASS SEAMING AUTOMATION

Modular Solution for Hostile and Heavy-Duty Application

THE CHALLENGE:

Glass processing is particularly demanding on linear motion components, with its abrasive environment and high production rates. Glass seaming is a common process where the sharp edges of cut raw glass are ground to a smooth finish. Seaming allows for safe handling and reduces chipping defects that can lead to breakages. This seaming machine has two pairs of grinding heads, each with one fixed head and the other moving automatically in and out to seek and find the parallel glass edge.

INDUSTRY: Glass Cutting

PRODUCT USED: HepcoMotion HDS2

HDS2 New Features

Larger bearings with Increased Load Capacity

Drive Shaft Handling

Automotive Application

Heavy Duty Slide System

Solar Tube Transfer from One Palette to Another

Low Maintenance Gantry System

Ultimate Heavy Duty Solution

Write Your Own Review