Inspection & Scanning

Bishop-Wisecarver products are the right motion systems for a variety of scanning and inspection applications across industries.

Laboratory/medical industry OEMs rely on Bishop-Wisecarver to deliver smooth and quiet motion, as well as corrosion resistance after sterilization.

In quality control applications, BW technology can smoothly and precisely traverse long lengths and curvatures.

Our guides, actuators, and complete automation systems supply reliable motion whether your equipment analyzes electronic assemblies or airplanes.

SMOOTH MOTION, LONG LENGTHS, & HIGH SPEEDS

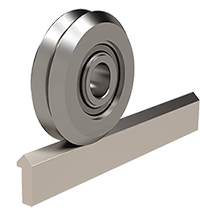

At the core of our systems and actuators is DualVee Motion Technology®. As vee wheels run on their matching track, the angled profiles wipe any debris out of the way. This self-cleaning action keeps the motion extremely smooth and running reliably.

- Corrosion resistant options – complete solutions with stainless steel, anodized aluminum, and polymer-overmolded components

- Vacuum-grade wheels ideal for lab, semiconductor, etc.

- Miniature linear guides (MinVee®) provide smooth motion in a low profile

Bishop-Wisecarver has solutions that range from manually operated slides to precise, rigid actuators.

DESIGN THE PATH YOU NEED

Design your optimal motion path for both speed and footprint by using BW linear, rotary, or complex curved systems.

Our vee track comes in base lengths up to 22 ft (~6.7 m) and can be joined end-to-end to create long linear systems without the costs of precision machining.

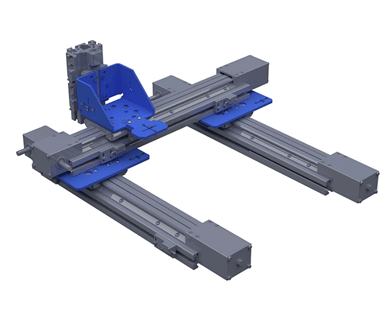

Take the guesswork out of creating a gantry or multi-axis inspection system – simply connect LoPro® Linear Actuators with a Gantry Kit.

Designing rotary tables, long transfer circuits, and indexed stations is easy with HepcoMotion® Precision Ring and Track and Driven Track Systems.

Vee guide technology can even combine with linear motors to offer highly versatile, independently driven carriage transfer at high speeds.

Bishop-Wisecarver is proud to be the exclusive North American distributor of HepcoMotion® products since 1984.

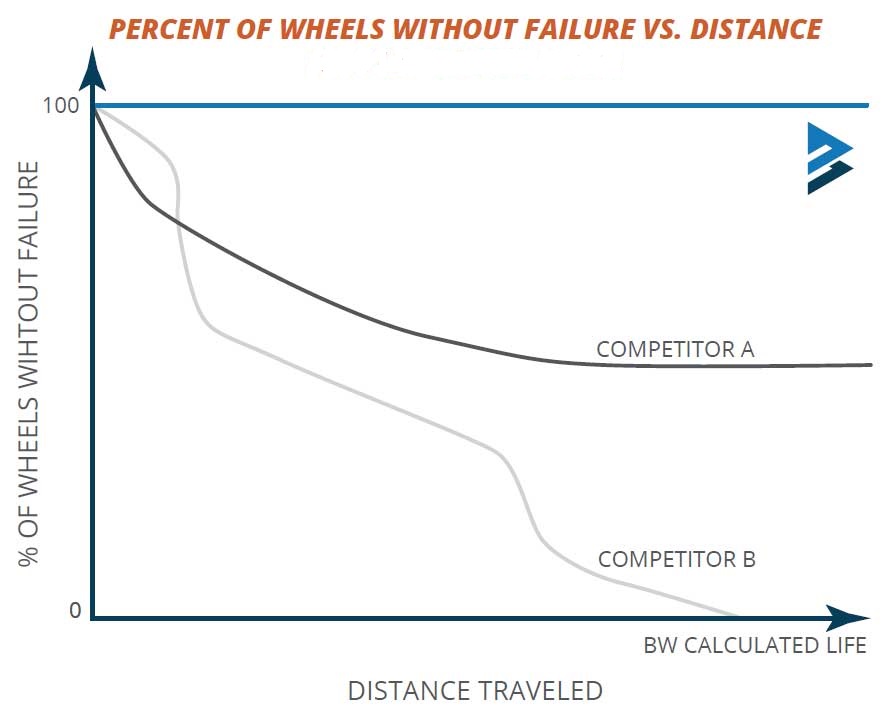

Long-Lasting Motion Systems

Importantly, BW systems inherently provide LONG LIFE with LOW MAINTENANCE. See how our DualVee® wheel and track systems outlast and outperform the competition in THIS WHITEPAPER:

GET THE RIGHT SOLUTION FOR YOUR TRANSFER APPLICATION

Our expert Application Engineers can help you design a motion system that meets all your application requirements - using standard or fully custom solutions.

Leveraging 70 years of experience, Bishop-Wisecarver has earned the reputation for providing unmatched service and engineering support for every stage of your design cycle.

Bishop-Wisecarver is a trusted and reliable partner for everything from standard catalog motion components to custom integrated motion and control systems. Our world-class engineering support and custom manufacturing capabilities offer unsurpassed design flexibility.

Complex Assemblies

- Electro-mechanical assembly

- Supply chain & assembly services

- Purchase order consolidation

- Vendor management

- Kitting

Motion Products

- Linear guide bearings

- Linear actuators & motion stages

- Rotary & curvilinear motion guides

- Multi-axis actuated systems

- Automated motion systems

Automation & Integration

- Mechanical motion system design

- Electronic controls engineering

- Software & motion system integration

- Motion control system analysis

Production Support

- Profile extrusion design & finishing

- CNC milling/turning, grinding

- Fabrication, prototypes, production

- Finish coating, anodizing, painting

Check out our product selector to learn more about the BW products that fit your needs or our CAD downloads to see our products in your design!

APPLICATION EXAMPLES

Scanning and Dimensioning with UtiliTrak Linear Guides

Bishop-Wisecarver helps manufacturers and automation solution providers engineer linear and rotary motion products.

Benchtop Immunoanayzer

A manufacturer of desktop analyzers required a compact and reliable method of positioning and scanning the testing kit trays.

PRODUCT USED: DualVee Wheels and Track

High Speed Printing System

The customer needed a slide system to move a print head or multiple print heads into printing position.

PRODUCT USED: LoPro

Download PDF of Inspection & Scanning Application Solutions