Packaging

We'll Provide You with the 'Total Package'

Bishop-Wisecarver guides and actuators provide high speed, high acceleration, and high durability. Our self-cleaning vee guide wheel technology wipes away dust and debris. This makes our solutions ideal for cutting, product transfer, scanning, or any other packaging operations requiring reliable uptime.

DURABLE AGAINST DEBRIS

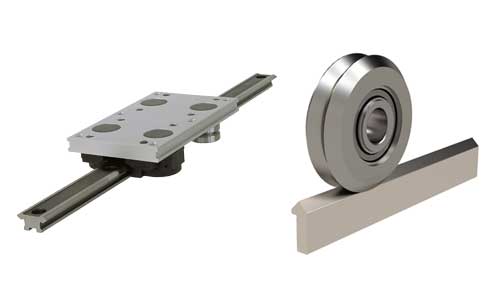

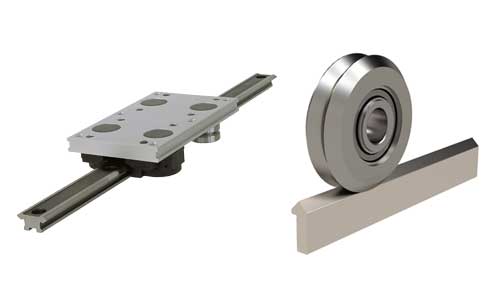

At the core of our systems and actuators is DualVee Motion Technology®. As vee wheels run on their matching track, the angled profiles wipe debris away, preventing buildup and motion system failure. DualVee Motion Technology® CLEANS ITSELF against debris and residue often found in processes such as boxing, cartoning, and wrapping:

- Paper, cardboard, and packaging particulate

- Adhesive residues

- Plastics and foam

- Wood debris

- Food product (dry, wet, or sticky)

- Fibers, dust, dirt, and more.

Fully sealed motion systems, protective covers, and sealed/shielded components add even more layers of protection as needed!

In addition to providing lasting solutions based on DualVee Motion Technology®, Bishop-Wisecarver is the exclusive North American partner and distributor for HepcoMotion® products since 1984.

DualVee®, UtiliTrak®, and HepcoMotion® GV3 are smooth-running and highly versatile guidance components that every packaging machine designer should have in their toolbelt.

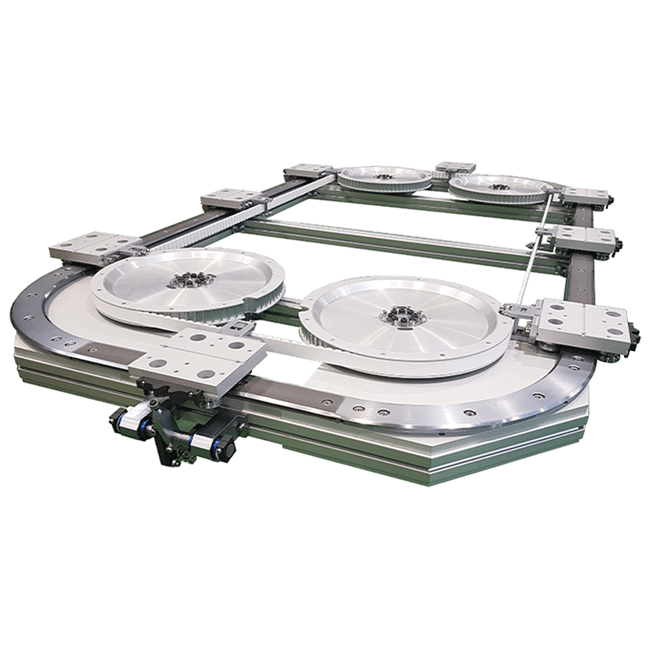

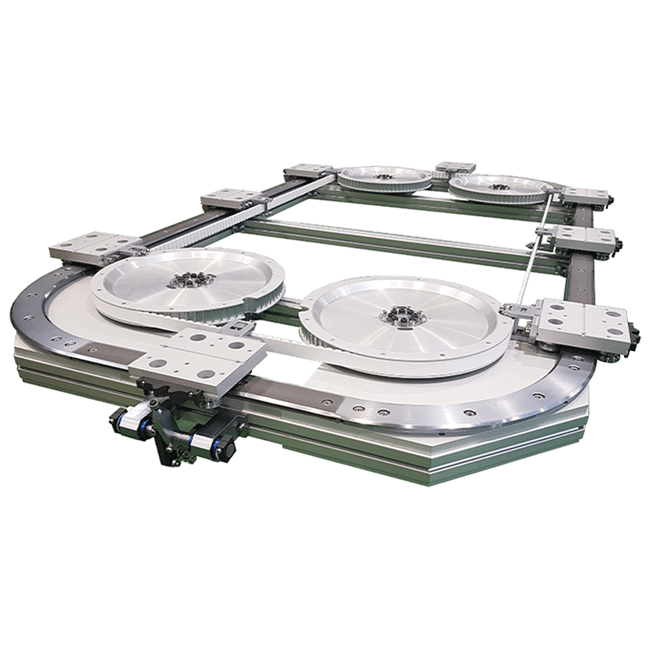

HepcoMotion® PRT2 disks and large open center rings provide rotary motion for orbital wrapping, slewing in bottling operations, and more.

UtiliTrak® compact linear guides are available for light to heavy duty guidance and are ideal for mounting in parallel installations. They allow smooth motion for scanning, machine adjustment, product or tool transfer, and more.

HepcoMotion GFX Hepco Guidance System for Beckhoff XTS Transport System is highly programmable and independently moves carriages for maximum flexibility. It allows near instant changeover between goods with varying assembly and packaging operations.

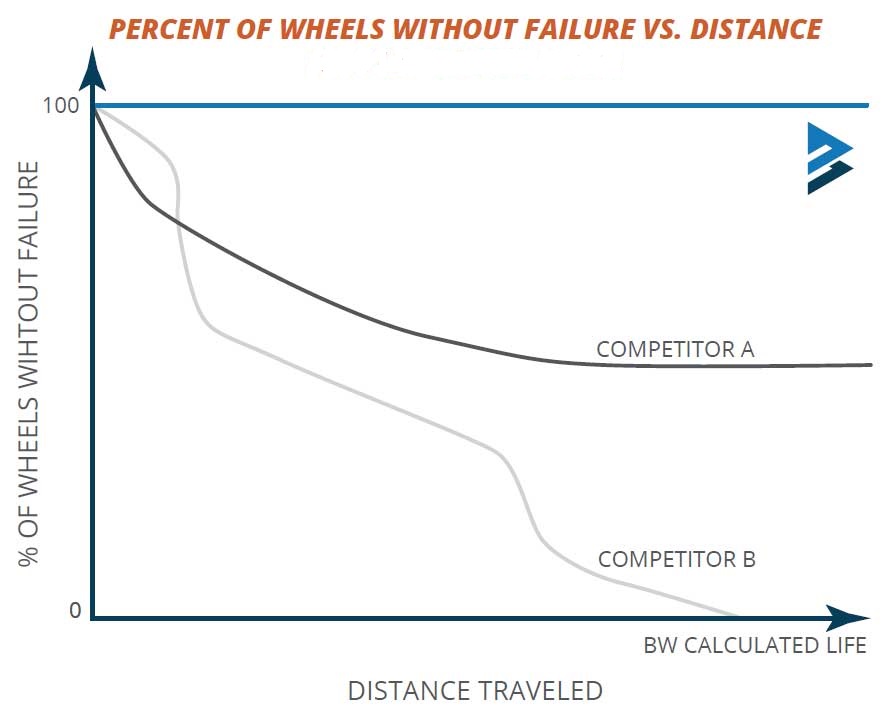

Long-Lasting Motion Systems

Importantly, BW systems inherently provide LONG LIFE with LOW MAINTENANCE. See how our DualVee® wheel and track systems outlast and outperform the competition in THIS WHITEPAPER:

ENHANCED THROUGHPUT

- Speeds up to 18 ft/s (5.5 m/s) and accelerations up to 5 g’s enable high throughput.

- Durability and low maintenance can reduce shutdown time for end users and increase profit.

- For flexible machines that must deliver quick changeover times, DualVee Motion Technology® enables smooth-running adjustment and fast assembly swapping.

- Design your optimal motion path for both speed and footprint by using BW linear, rotary, or complex curved systems.

EXCEL IN THE TOUGHEST ENVIRONMENTS

In addition to high debris and high throughput applications, Bishop-Wisecarver provides solutions for your toughest motion challenges.

- Hygienic and food grade: Stainless steel construction + H1 grease OR without lubrication

- High load and moment capacity options to move entire packaging machine subassemblies

- Extremely smooth motion over any length – well-suited for printing, scanning, and more

GET DESIGNING FAST

Our expert Application Engineers can help you design a motion system that meets all your application requirements - using standard or fully custom solutions.

Check out our product selector to learn more about the BW products that fit your needs or our CAD downloads to see our products in your design!

If you’re designing a gantry or multi-axis system visit our gantry page to learn more.

APPLICATION EXAMPLES

Space Efficient, Low Maintenance

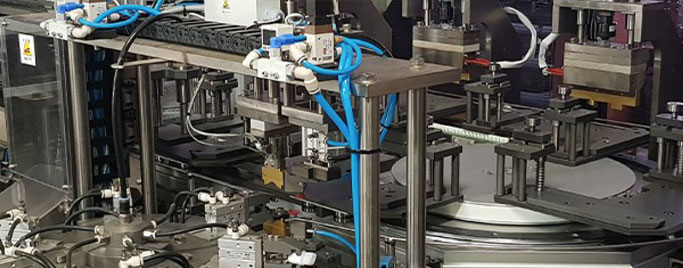

When South Korean automation manufacturer New Hanil Engineering was commissioned to develop a machine to fully automate the production of liquid detergent packaging, it was essential to build a space-saving, low maintenance system that would provide the high throughput required. The machine produces spout pouches, one of the fastest growing packaging formats that offer a flexible, cost-effective alternative to plastic bottles. At the core of the machine, New Hanil required a precise and reliable carousel system to guide and transfer the spout packs around the system.

PRODUCT USED: DTS Driven Track System

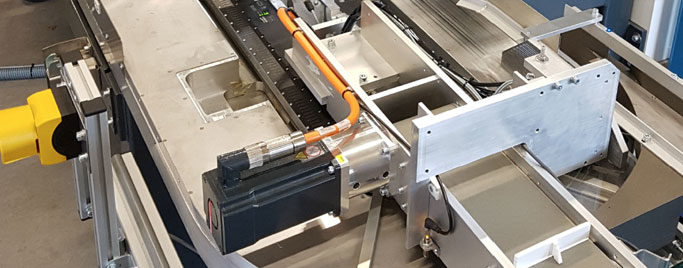

Solution Allows On-the-fly Changes

One of the key challenges Smart Automation faced was finding a guidance system that could be safely built into the core of the new machine. The system needed to run for several years without maintenance and their search was not initially successful. Smart Automation’s designers looked at a number of manufacturers before finally deciding to use HepcoMotion, one of the leading manufacturers in the field of linear guidance systems. “Quality and price convinced us,” says Roland Mulder, project manager for Smart Automation.

PRODUCT USED: GFX - Guidance System

Download PDF of Packaging Application Solutions

Download PDF of Packaging Industry Segment