Cutting

Bishop-Wisecarver products are the right fit for automated cutting and slitting applications because they provide maximum durability against debris; They are built to last, even when operating high-throughput machines and extreme conditions.

DURABLE AGAINST DEBRIS

At the core of our systems and actuators is DualVee Motion Technology®. As vee wheels run on their matching track, the angled profiles wipe debris away, preventing buildup and motion system failure. DualVee Motion Technology® CLEANS ITSELF against cutting debris – large, fine, wet, and highly abrasive:

- Metal chips and dust (in both dry and wet cutting environments)

- Residual particulate from abrasive waterjet splash back

- Dross / slag from plasma cutting

- Glass shards and dust (dry or wet cutting, grinding, and seaming)

- Carbon fiber

- Paper, cardboard, and packaging particulate

- Wood debris

- Food product (dry, wet, or sticky)

- Plastic swarf and particulate

- Fibrous materials, such as textile fibers

- Cutting operations in the presence of dirt, dust, and adhesives

Fully sealed motion systems, protective covers, and sealed/shielded components add even more layers of protection as needed!

Long-Lasting Motion Systems

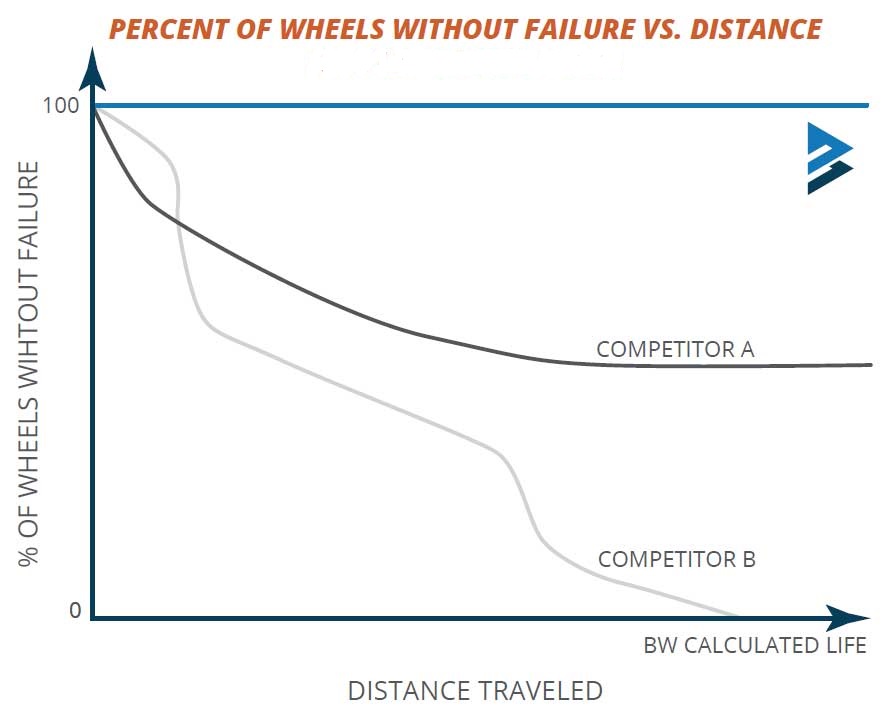

Importantly, BW systems inherently provide LONG LIFE with LOW MAINTENANCE. See how our DualVee® wheel and track systems outlast and outperform the competition in THIS WHITEPAPER:

ENHANCED THROUGHPUT

- Speeds up to 18 ft/s (5.5 m/s) and accelerations up to 5 g’s enable high throughput cutting and slitting processes.

- Durability and low maintenance can reduce shutdown time for end users and increase profit.

- For flexible machines that must deliver quick changeover times, DualVee Motion Technology® enables smooth-running adjustment and fast assembly swapping.

- Design your optimal motion path for both speed and footprint by using BW linear, rotary, or complex curved systems.

EXCEL IN THE TOUGHEST ENVIRONMENTS

In addition to high debris and high throughput applications, Bishop-Wisecarver provides solutions for your toughest motion challenges.

- Hygienic and food grade: Stainless steel construction + H1 grease OR without lubrication

- Caustic washdowns: BW patented high-pressure wheel seal

- High temperatures (up to 500 °F / 260 °C)

- Low temperatures (down to -94 °F / -70 °F)

- High load and moment capacity options to move entire cutting machine subassemblies

GET DESIGNING FAST

Our expert Application Engineers can help you design a motion system that meets all your application requirements - using standard or fully custom solutions.

Check out our product selector to learn more about the BW products that fit your needs or our CAD downloads to see our products in your design!

Click here to learn more if you’re designing a gantry or multi-axis system.

APPLICATION EXAMPLES

Glass Cutting and Recycling

Glass dust was playing havoc on the ball race linear bearings. Dust was infiltrating the travel table bearings and transport assembly which caused a build-up of glass and, ultimately, premature failure.

PRODUCT USED: GV3

Plasma Pipe Cutting

To guide the plasma cutting heads along a prescribed circular path, a ring-shaped high-performance guide system was required that can meet the required operating times free of faults.

PRODUCT USED: HDRT

Food Cutting Automation

DualVee® wheels and track provided a long-lasting, self-cleaning solution. The unique washdown seal system retains the bearing grease during high pressure cleaning, ensuring the bearings stay lubricated for life.

PRODUCT USED: DualVee Wheels and Track

Glass Seaming Automation

This equipment manufacturer used HDS2 systems. The durable HDS2 ensures the speed, process flexibility, and precision requirements of the end user’s seaming operations.

PRODUCT USED: HDS2

CNC Mill - Cutting Equipment

Whether cutting wood, metal, fiberglass, or other material, CNC routers must tolerate the resulting dust and debris to get the job done. Both ShopBot and their customers need axes that exhibit smooth motion without binding.

PRODUCT USED: UtiliTrak

Download PDF of Cutting Application Solutions