Welding

Bishop-Wisecarver is a leader in guided motion for welding and plasma cutter automation in construction machinery, the automotive industry, and beyond.

Whether you require long linear motion for a CNC plasma cutter, rotary motion for orbital welding, or heavy duty robotic transfer units, BW can help you meet your specific application needs. Our solutions are designed to provide durability and smooth motion despite the high temperatures and molten metal debris experienced by welding machinery.

SMOOTH MOTION IN HARSH & EXTREME WELDING ENVIRONMENTS

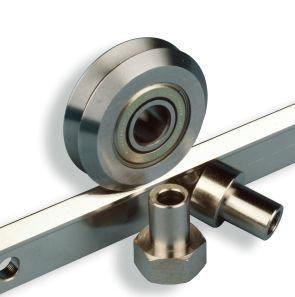

At the core of our systems and actuators is DualVee Motion Technology®.

High Temperature DualVee® wheels can operate in temperatures up to 500 °F (260 °C).

Additionally, as vee guide wheels run on their matching track, the angled profiles wipe away weld spatter, dust, and other debris. This self-cleaning action keeps the motion extremely smooth and prevents buildups that could lead to motion system failure.

High load and moment capacity options allow smooth guided motion of entire machine subassemblies and industrial welding robots.

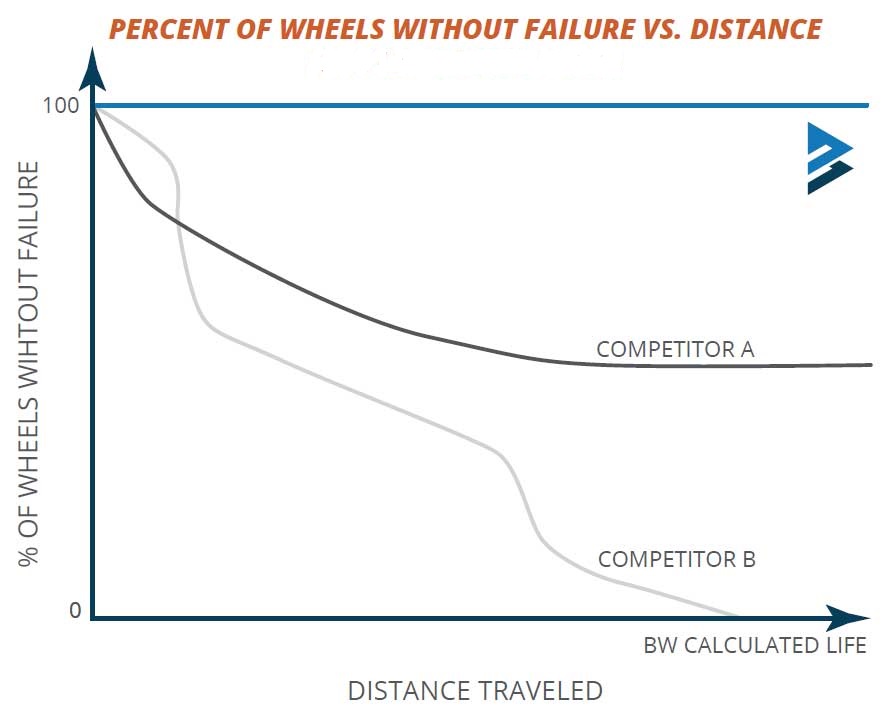

Long-Lasting Motion Systems

Importantly, BW systems inherently provide LONG LIFE with LOW MAINTENANCE. See how our DualVee® wheel and track systems outlast and outperform the competition in THIS WHITEPAPER:

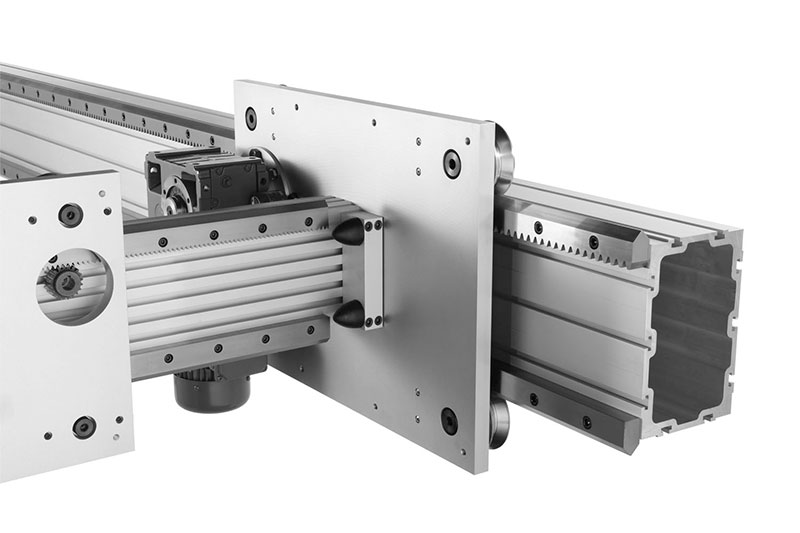

LINEAR, ROTARY, AND GANTRY SOLUTIONS DESIGNED FOR EASE OF INSTALLATION

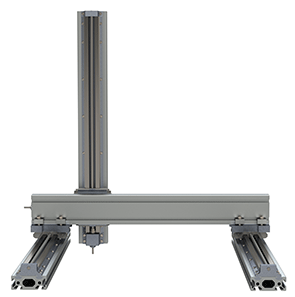

Take the guesswork out of creating a gantry or multi-axis system – simply connect LoPro® Linear Actuators with a Gantry Kit.

Additionally, vee guide wheels easily and smoothly traverse small gaps in linear or rotary track. For example, in an orbital welding application, this means that ring segments for guiding the weld head can be separated to fit over a pipe.

The wheels and track can also be fully disengaged from each other as needed (e.g. to remove a weld head assembly for maintenance).

GET THE RIGHT SOLUTION FOR YOUR WELDING APPLICATION

Our expert Application Engineers can help you design a motion system that meets all your application requirements - using standard or fully custom solutions.

Check out our product selector to learn more about the BW products that fit your needs or our CAD downloads to see our products in your design!

APPLICATION EXAMPLES

Train Welding Application

Bishop-Wisecarver HepcoMotion GV3 reduced the downtime of this train welding system, which previously failed due to misalignment and ingress issues.

Plasma Pipe Cutting

Two heavy-duty ring systems provided the durability needed in the extreme environment. These rings feature vee guide technology that delivers a selfcleaning action, which means that any contamination is wiped away by the vee bearings.

PRODUCT USED: Heavy Duty Ring & Track

Welding Inside Broilers

The DualVee® wheels and track allowed quick removal for servicing. In addition, because of the reliability and durability of Bishop-Wisecarver’s products, the new design had a longer lifecycle and needed less maintenance than the previous system.

PRODUCT USED: DualVee Wheels and Track

Download PDF of Welding Application Solutions