Forget dusty factories – today's manufacturing is a high-tech wonderland of opportunity. Discover how a career in this innovative field could be your gateway to shaping the future while enjoying stability and growth.

Engineering

-

Posted: October 09, 2024||Read more »

-

Posted: July 28, 2021||Read more »These competitor products fail to perform to the same levels as DualVee®, and their product limitations not only hinder machine reliability, but also increase the total cost of ownership (TCO) for customers.

-

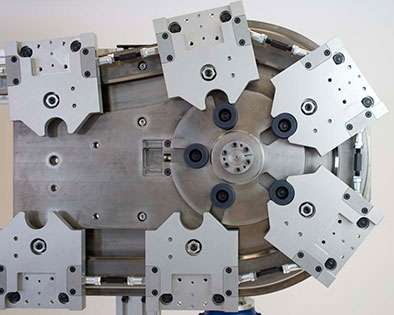

Posted: June 30, 2021||Read more »What do 7th axis robots, indexing assembly lines, and pick-and-place gantries have in common? They all count on reliable transfer technology.

-

Posted: December 22, 2020||Read more »Hopefully, all your shopping is complete for 2020, but let us give you a head start on that holiday wish list for next year: Consider a vibrating pillow designed to give you a better night sleep for a more productive day in front of the computer. While it isn’t actually in production (yet!) this was the winning idea submitted by Ramzi Latreche, a senior at Ygnacio Valley High School in California, for the inaugural Wisecarver Innovation Award student design contest.

-

Read more »Happy 50th Anniversary to the celebration of Earth Day! The first event in 1970 included approximately 10 percent of the US population that year—20 million people —and is credited with launching the modern environmental movement.

-

Read more »Both track-based systems and conveyor-based systems can shuttle materials from point A to B…but how do you choose one over the other? Environmental factors, desired machine footprint and application requirements such as speed and precision, all play a role in the decision process, and the ultimate success of that choice.

-

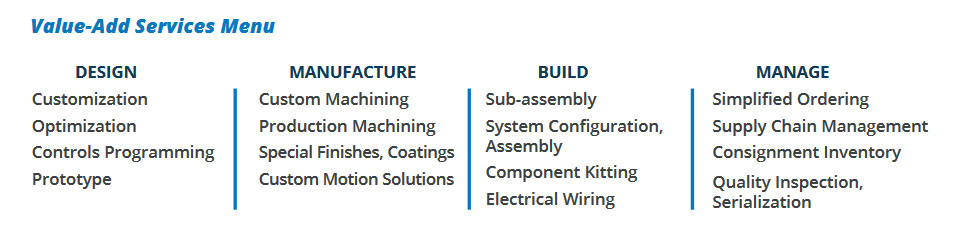

Read more »At Bishop-Wisecarver, we’ve manufactured patented motion products for nearly seventy years. We take pride in offering our customers a large variety of durable options that provide a low total cost of ownership. From the materials used, to the manufacturing processes we have in place, are what our customers have told us to be the best in the business.

-

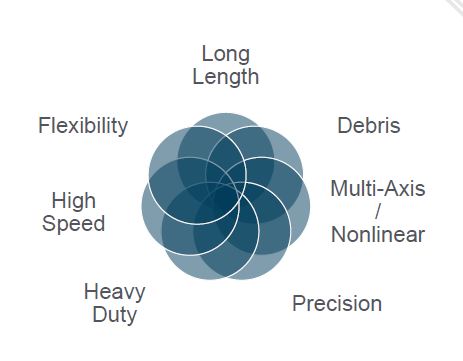

Read more »Finding the right motion product for any automation project just got easier with Bishop-Wisecarver’s Product Selector tool. Customers easily and quickly answer 5 short questions and the Product Selector tool provides a list of products that match their stated requirements. The list includes each product’s image, description and links to additional info. The entire process takes less than 2 minutes, saving customers valuable time and giving them confidence in researching the best product for their individual needs.

-

Applications in harsh and contaminated environments often exhibit low durability or premature failure which require frequent service or replacement. Either option means additional time and money spent, and often, a loss of revenue for machinery down time during the process. It causes multiple challenges for busy companies, which is why Bishop-Wisecarver has focused on manufacturing linear motion products that can withstand these extreme environments.Read more »

-

Bishop-Wisecarver president, Pamela Kan, was interviewed on the Women and Manufacturing podcast late last year.Read more »

Pamela A. Kan is a second-generation manufacturer where she serves as President of Bishop-Wisecarver in Pittsburg, CA. Pamela is a leader in manufacturing and an advocate for ensuring the next generation of makers are inspired to join the industry.