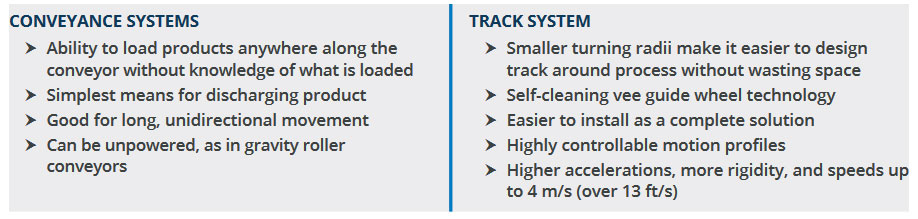

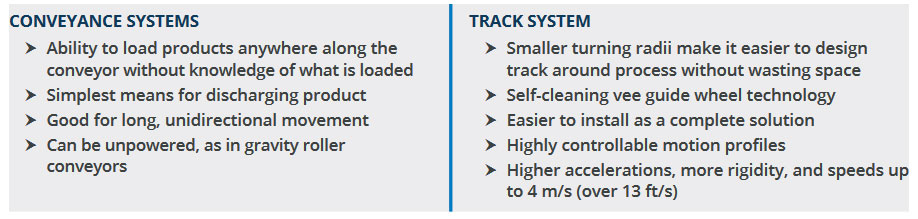

Both track-based systems and conveyor-based systems can shuttle materials from point A to B…but how do you choose one over the other? Environmental factors, desired machine footprint and application requirements such as speed and precision, all play a role in the decision process, and the ultimate success of that choice.

As this shows, applications requiring simple movement of goods realize the most from conveyor systems. But several applications that often include conveyor systems should consider moving to track for greater success. Read details here about the benefits of track systems when you need:

- Bulk Material Handling

- Precision: Indexing with high throughput

- Versatility: Complex operations and multi-product handling

- Resilience: Debris and moisture

When it’s time to choose, remember this rule of thumb: Applications requiring simple movement of goods can utilize conveyor systems. But applications that require curves, process stops, protection from excessive debris, increased flexibility and precision, should utilize track systems with vee guide motion technology as the best option.