If you can’t stand the heat, get out of the kitchen. Or in this case, if your products can’t withstand the heat, step aside as this is where Bishop-Wisecarver excels. Just ask our long-time customer, Mavrix Welding Automation of Wisconsin. Mavrix designs and builds standard and custom machines for special purpose welding and fabrication. Their customers include agriculture, oil & gas, recycling, and steel manufacturing industries that need robust and durable machines built to last.

In more than 20 years as a customer, Mavrix has relied on Bishop-Wisecarver’s DualVee wheels and track to withstand the high temperatures, destructive contaminants and demanding duty cycles inherent in welding operations. Reliability and serviceability are paramount for the critical capital equipment they provide and Glen Senger, President of Mavrix says, “Traditional carriages and rails just don’t hold up in this world.”

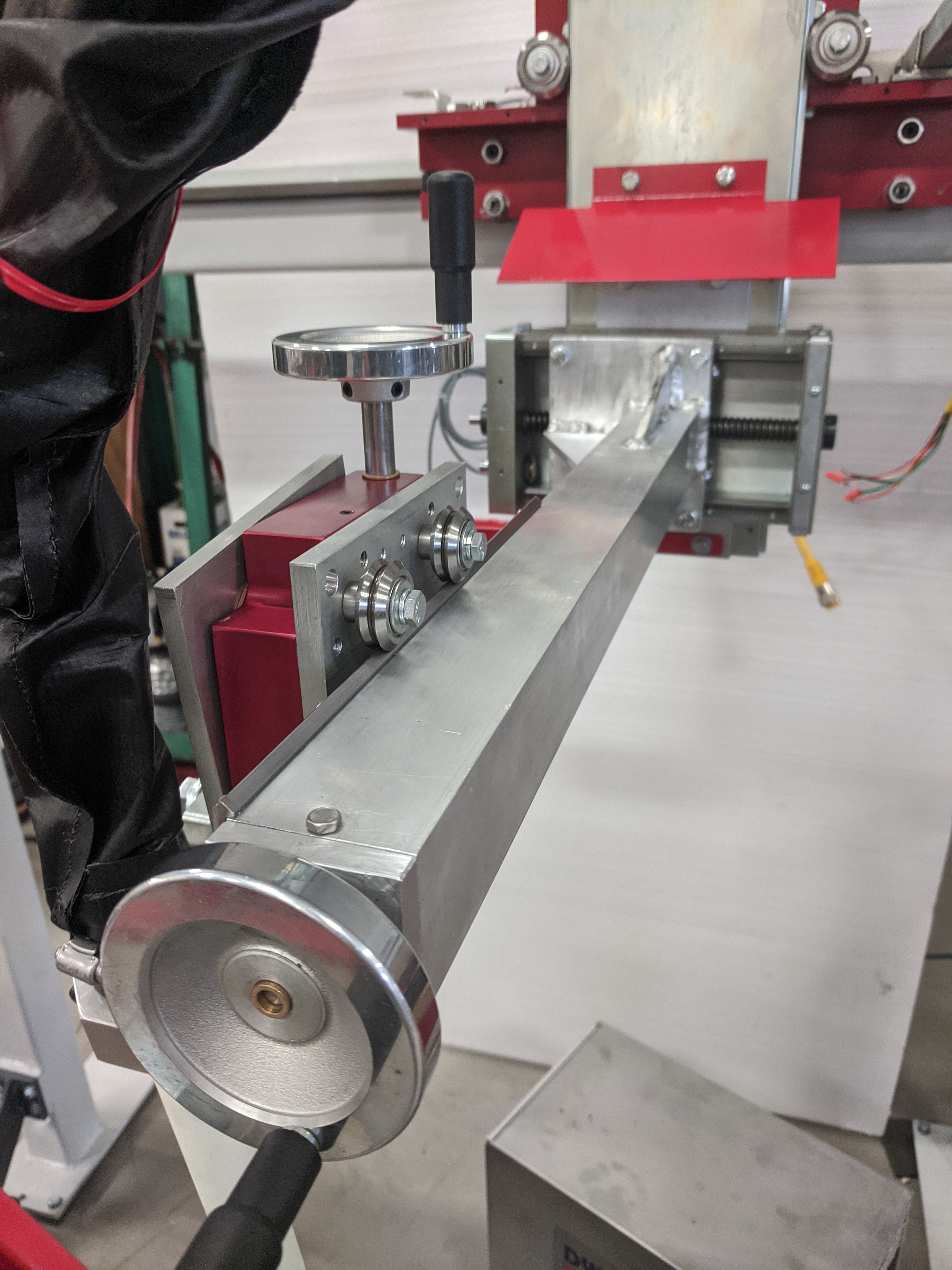

One of their new automated welding machines requires smooth motion on 3 axes and they specified DualVee guide wheels and track for each axis. The self-cleaning action, durable construction, and sealed bearings are lubricated for life providing long-time use with little maintenance and downtime.

Check out this application story for more details about long-lasting Bishop-Wisecarver products and go to our website to learn more about DualVee guide wheels and track.