Manufacturing isn't a career where you check your brain at the door. It needs great problem solvers who work to meet current customers' needs, while also developing new innovations for future concerns. The 2015 public perception report by Deloitte and The Manufacturing Institute found that 78 percent of millennials said their decision to work at a company was influenced by how innovative they considered the company to be and having the chance to make a difference.

Manufacturing isn't a career where you check your brain at the door. It needs great problem solvers who work to meet current customers' needs, while also developing new innovations for future concerns. The 2015 public perception report by Deloitte and The Manufacturing Institute found that 78 percent of millennials said their decision to work at a company was influenced by how innovative they considered the company to be and having the chance to make a difference.

Manufacturing is all about innovation and Bishop-Wisecarver engineers enjoy the ability to take their schooling and innate interests and make a difference by creating something new that can help a customer. From product customization to engineering support, installation, training and education – engineers help every step of the way.

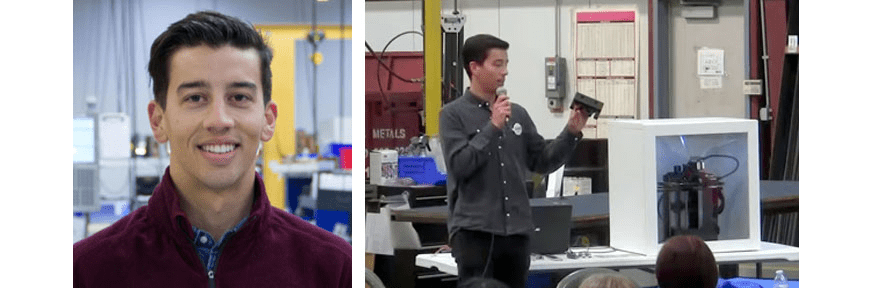

It’s exciting to see more young engineers, like Nils Severson, joining the manufacturing industry and realizing the long-term difference they can make.

About Nils Severson

Nils joined our Bishop-Wisecarver in 2015 as a recent college graduate with a bachelor’s degree in Mechanical Engineering from California State University, Sacramento.

Q: What is your job function at BW?

NS: My job is to review what the customer wants to make – usually by looking at CAD drawings - and then interpret and create the processes for production. I act as a bridge between production and engineering.

Q: What do you enjoy most about your job?

NS: I enjoy the variety of my job. One day, I can be focused on designing a fixture or a machine to complete a specific task and the next, I’m trying to improve a process or figure out the root cause of some problem.

I also enjoy learning about, and designing, products that are going to last over the long haul in extreme and harsh environments. Many of our customers know this is our specialty and we have products in the field that have been working continuously for years in cold, hot, dirty or even ultra clean places. This takes a unique design and manufacturing process that I like working with.

Q: What has been one of your most challenging projects and what was the outcome?

NS: I was working to redesign a machine to open up more capability for that machine. It was challenging because it was not a standard machine and every part was custom. I had to document the entire machine using CAD; then model the new version on top of the old to make sure the new design would fit existing mounting holes and spatial constraints. I was able to design, make the parts and then test them on the machine. After all the parts were installed, the machine operated as planned.

Q: Who is your mentor and how did they best help you?

NS: My Uncle was my mentor. He taught me his process of taking apart cars and how you need to be an investigator to determine the root cause of a problem, i.e. engine not starting.

Q: Why did you choose a career in engineering?

NS: I like creating things and I like figuring out how things work. Engineering lets me do both.

Q: What advice would you give students interested in engineering and/or manufacturing?

NS: Keep building things. Try and make it before you buy it. For example, try to build a bicycle, a table or video game console. The process of thinking about how to make all of those things will help you learn even if you don’t end up actually building it. If you do build it, you will begin to understand the practical side of manufacturing something.

Q: What are your interests outside of work?

NS: I like to mountain bike, surf and work on cars.