This is Part 2 of our Linear Actuator Selection Guide. If you haven't read Part 1 on guide types, start there first.

2) Drive Mechanisms

Working in tandem with guides, are drives. Drives have a lot of control over the speed, smoothness, load capacity and travel lengths. There are many different types of drive mechanisms, and, like the guide types, they feature specific advantages and disadvantages that are directly applicable to the kind of work you need your actuator to do. It is knowledge of these advantages and disadvantages that will help you to further hone in on the best drive type for your motion system.

Undriven Manual Power

Advantages:

• Lower cost

• Meets basic requirements

• Minimal lead-time

Limitations:

• Limited load/force capacity

• Poor accuracy

• Inefficient

Roller Chain with Chain Sprockets

Advantages:

• High thrust load capacity

• Cost-effective for long travel applications

Limitations:

• Limited speed

• Moderate to low linear accuracy

• Backlash and chain stretch over time

Lead Screw

Advantages:

• High linear accuracy

• Can be non-back driving

• Moderate cost

• Self-locking in some configurations

Limitations:

• Low speeds

• Travel length restrictions

• Relatively long lead-time

• Relatively clean environments

• Moderate maintenance

Belts, Toothed Belts, Drive Belts

Advantages:

• Very high speeds

• Very long travel lengths

• Short lead times

• Low maintenance requirements

• Cost effective

• Various standard sizes

Limitations:

• Moderate linear accuracy

• Belt stretch maintenance

• Wear and abrasion polymer teeth

• Lower tensile strength

Gear Rack and Pinion

Advantages:

• Medium to high linear accuracy

• Various precision available

• Low precision cast teeth

• High precision ground teeth

• Very long travel lengths

Limitations:

• Low to medium speeds

• Noise generation

• Relatively high costs

• May require shielding and consistent lubrication in dirty environments

• Lubrication is critical

• Moderate maintenance requirements

Ball Screw

Advantages:

• High linear accuracy

• High mechanical efficiency

• High thrust loads

Limitations:

• Back-drivable

• Low to moderate speed

• Travel length restrictions

• High cost & long lead-time

• High maintenance requirements

• Clean environments

Linear Motor

Advantages:

• Direct linear force output without rotary-to-linear conversion

• Force is applied with no Intermediary

• No Friction for Linear Motion

• Ideal for Linear Motion

• Very High Accuracy and Repeatability

• Very high speed

• No mechanical wear

Limitations:

• Higher Cost

• Lower Stiffness than Contact Elements

• Susceptible to Vibration

• Complex Motion

• Control Electronics

• Higher Heat Generation

3) Couplers and Design Considerations

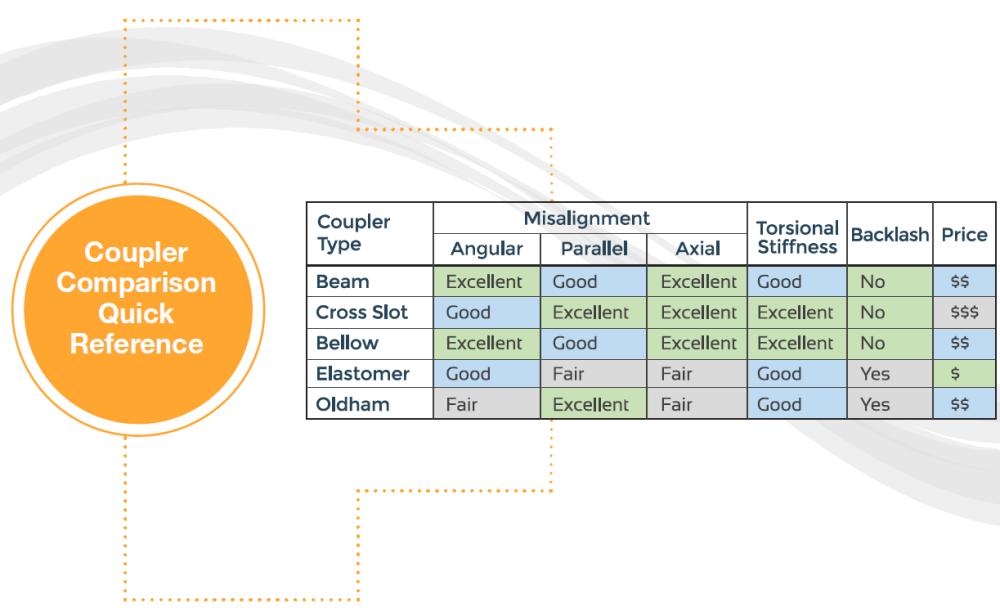

Now that you’ve been reacquainted with the various advantages and disadvantages of guide and drive types for linear actuators it’s a good idea to have a refresher on coupler types and a few important things to consider during your design.

Before selecting a coupler, evaluate:

- Have I considered the physical size?

- Have I considered misalignment from machining?

- Have I evaluated the amount of torque during operation and peak conditions?

- Have I considered torsional stiffness of the coupler?

Coupler Comparison Quick Reference

Conclusion

Choosing a linear actuator doesn’t have to be difficult, but it does require proper consideration. Using a systemic method of assessment, such as a checklist, will help you to stay focused on the things that matter most to your application.

Being well versed in the pros and cons of both guide and drive types may be the difference between overspending and saving thousands! Take time with your decision-making process, use systematic assessment methods, and when in doubt, consult with a Bishop-Wisecarver® application engineer who can guide you through the complexities.