Industrial automation has transformed manufacturing, enabling processes that would be impossible for humans to sustain. We're not built for repetitive precision, our bodies tire, our accuracy falters, and prolonged bending or stooping takes its toll. This is where linear actuators become essential.

A linear actuator converts rotary motor motion into linear movement, making it possible to move heavy loads quickly and repeatedly with consistent precision. Whether you're automating a production line or building a custom motion system, choosing the right actuator can mean the difference between success and thousands in wasted investment.

The Three Pillars of Actuator Selection

When evaluating linear actuators for your application, focus on three critical components: Guide Type, Drive Type, and Coupler.

1) Guide Types

Guide types are where the movement of your actuator comes from. Although any guide type will move your actuator, it is important to know what guide types work best for what applications. Follow our basic checklist is a start to putting you on the right actuator path:

- What load capacities can it handle?

- What travel lengths will it support?

- What speeds is it capable of?

- How important is accuracy to my application?

Getting these right requires understanding both your application requirements and the trade-offs each option presents.

Guide Wheels

Advantages:

• Moderate accuracy

• Very long travel lengths

• Smooth, quiet, low friction motion

• Speeds to 5.5 m/s accelerations to 5gs

Limitations:

• Lower accuracy than square rail

• Moderate rigidity and stiffness

• Process to adjust preload

• Larger size vs. Load capacity

DualVee® is Bishop-Wisecarver’s proprietary guide wheel technology used in many actuator platforms, including LoPro® Linear Actuator. It features a 90° vee guide wheel and track interface that creates a natural self-cleaning action, ideal for environments with dust, debris, or liquid contaminants. While it offers low-friction, smooth motion over long distances and reduces maintenance, it is typically selected for applications where moderate accuracy and robustness are prioritized over ultra-high precision.

Ball Bushing, Round Rail, Round Shaft

Advantages:

• High load capacity vs. Size

• Low friction motion

• Capable of moderate accuracy

• Medium to low cost

Limitations:

• Relatively low speeds

• Difficult to mount on flat surfaces

• Relatively short travel lengths

• Contaminants may jam the ball races

• Balls may fall out when removed from the rail

Sliding Element Bearing

Advantages:

• Simple sliding design

• No moving parts

• Debris tolerant

• Good load capacity

• Speeds up to 4 m/s

• Low friction motion

• Medium accuracy

• Low friction materials

PTFE

UHMW

Polymers

Limitations:

• Can bind more easily

• Higher “sticktion” or “stick-slip”

• Faster wear characteristic

• Difficult to mount on flat surfaces

• Requires multiple blocks to prevent rotation

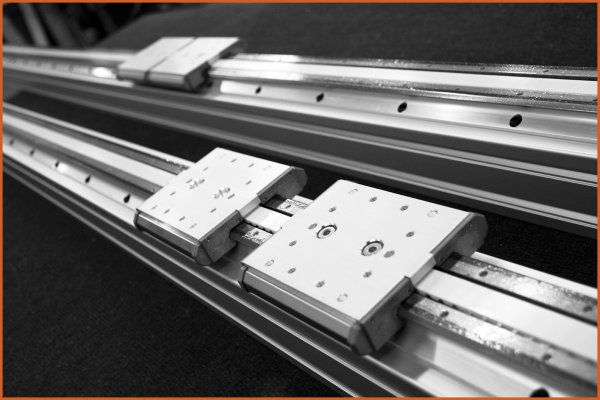

Square Rail, Profile Rail, Ball Rail

Advantages:

• Four row angular contact

• Very high load capacity vs. Size

• Low friction motion

• Very high accuracy

Limitations:

• Noise of ball contact

• Requires precision mounting surfaces

• Relatively short travel lengths

• Contaminants may jam the ball races

• Balls may fall out when removed from the rail

Non-contact, Air Levitated, Magnet Levitated

Advantages:

• No sliding friction

• Consistent velocity

• Capable of very high

• Accuracy

• Repeatability

• Velocity

Limitations:

• Very high cost

• Lower stiffness than contact elements

• Susceptible to vibration

• Complex motion

• Control electronics

• Higher heat generation

Making Your Selection

Guide type selection requires balancing multiple factors. A guide wheel system might offer the travel length you need, but fall short on accuracy requirements. Square rail provides precision but demands careful mounting preparation.

The key is matching guide characteristics to your application priorities. In Part 2, we'll explore drive types, couplers, and critical design considerations to complete your actuator selection process. Stay tuned!