LoPro® Robot Transfer Units

Both traditional and collaborative robots can benefit from Bishop-Wisecarver 7th Axis Robot Transfer Units. LoPro® RTU-L and LoPro® RTU-M are available for light and medium capacity applications. Each system is designed for durability, ease of installation, and low total cost of ownership. Our expert application engineers can help you select the complete 7th axis system solution that is right for you, or customize a solution to meet your exact requirements.

Chat with us to learn more about this product.

- Product Info

- Specification

- Success Stories

- Faqs

- Reviews

Add extremely durable 7th axes and robot transfer units (RTUs) for your favorite robot brands

Support and transfer robot arms of any size with Bishop-Wisecarver’s suite of robot transfer solutions. We provide reliable, long-lasting RTUs and 7th axis systems for all your favorite brands of cobots and industrial arms.

Our expertly designed robot transfer systems excel in even the harshest environments and most extreme applications. Each system is built on DualVee Motion Technology® for self-cleaning guidance, low maintenance, and unparalleled dependability.

Many solutions that run on DualVee guide wheels require no maintenance over the planned life of the machine. This ability to excel in critical applications makes Bishop-Wisecarver's solutions ideal for drilling, welding, painting, and more.

LoPro RTU-L and LoPro RTU-M

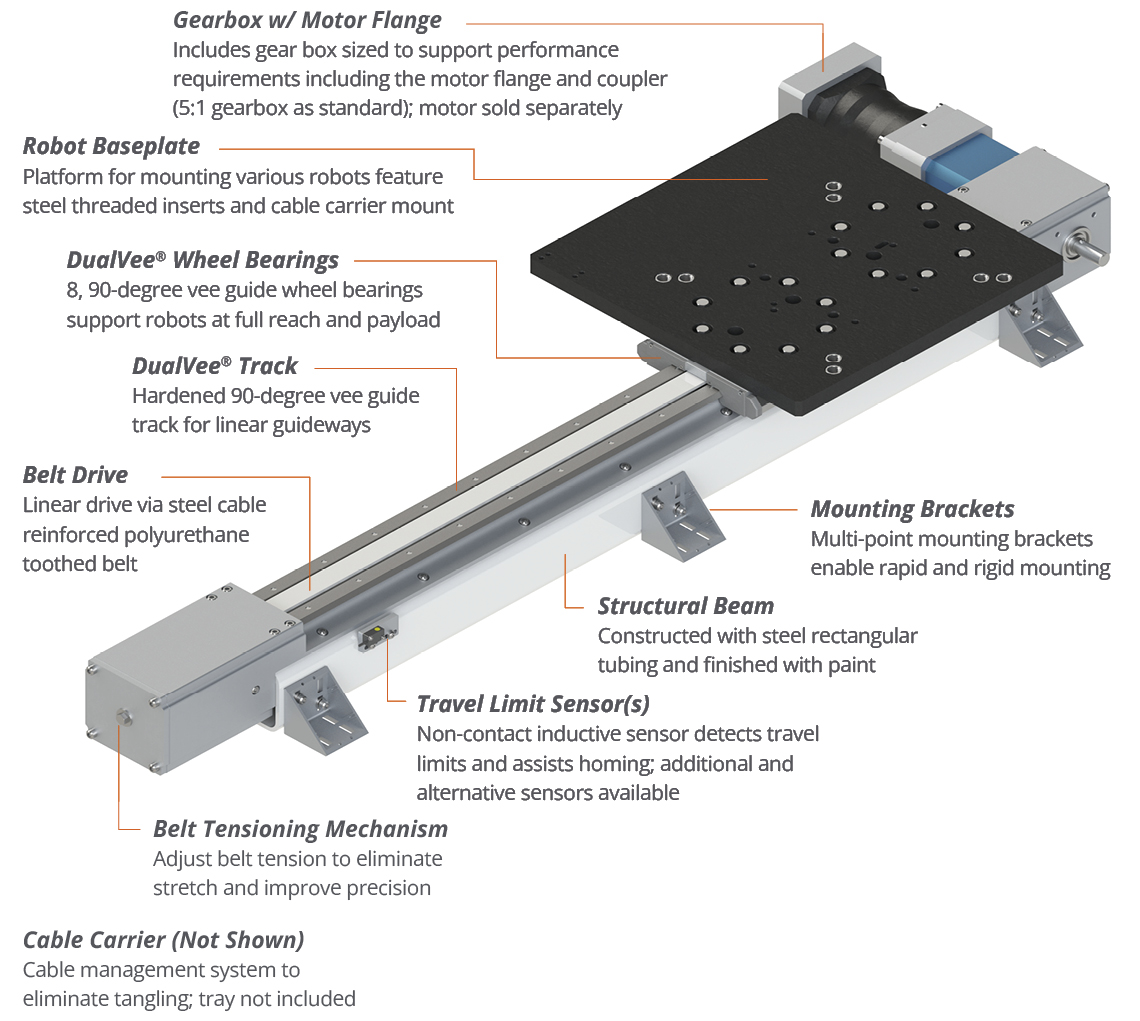

Includes:

- Belt-driven actuator with single wheel plate (RTU-L) or double wheel plate (RTU-M)

- Mounting plate with hole pattern matched to your robot

- Travel limit switch to assist homing

Accessories (sold separately):

- 5:1 planetary gearbox with motor mount matched to your drive motor of choice

- Motor package with servo, drive, and motor / encoder cabling

- Cable carrier kit for standard or inverted system mounting

- Additional homing / travel limit switches

You can get a complete RTU solution - simply provide the robot and its cabling!

Standard Features:

- Debris-resistant and extremely durable DualVee wheels

- Ready-to-mount bracketing assembled on a rigid steel base

- Belt tensioning and wheel adjustment systems designed for easy maintenance

- Painted base and anodized plates/brackets

Need customization? Talk to us!

- Custom lengths

- Removing included elements

- Alternate gearbox or motor package

- Cable carrier with pre-installed cables or alternate configurations

- Additional drive shaft (opposite the motor mounting side, for coupling etc.)

- Additional machining or alternate finishing

Inverted Mounting

The LoPro RTU is capable of inverted mounting with several robot configurations. Cable carrier kits suited to this orientation make inverted installation even easier. Try out a LoPro RTU inverted to save space in your application!

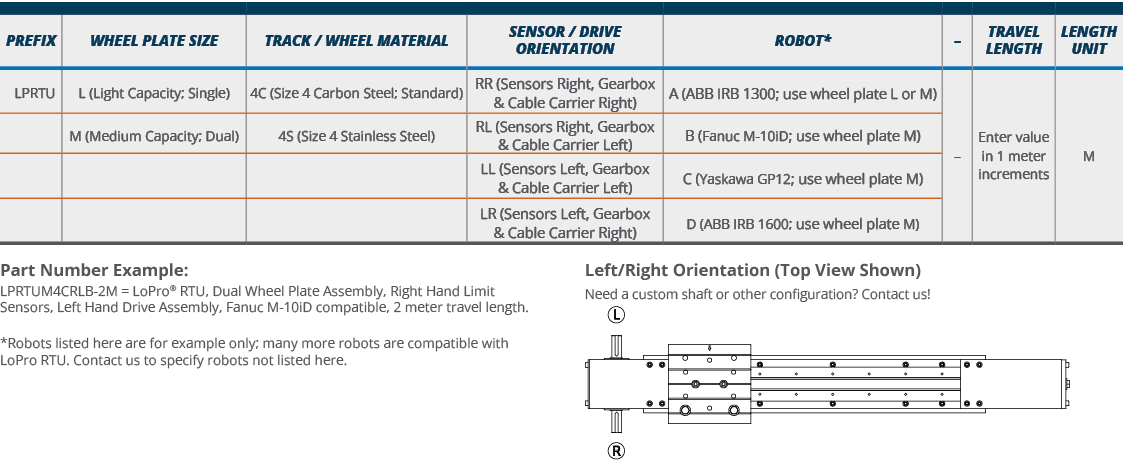

Stock Codes

System Capabilities

|

Vertical Force |

Horizontal Force |

Vertical Moment |

Horizontal Moment |

Horizontal Moment |

Thrust |

|

|---|---|---|---|---|---|---|

| N | N | N-m | N-m | N-m | N | |

LoPro RTU-L

|

15684 | 19012 | 1478 | 1174 | 1220 | 2818 |

LoPro RTU-M

|

31368 | 38024 | 2956 | 2348 | 2440 | 2818 |

7TH AXIS FOR ROBOTIC SANDING

Durable and Easy-to-Implement Robot Transfer Solution

THE CHALLENGE:

GrayMatter’s Scan&Sand™ system needed to consistently

produce superior results while sanding variable workpieces. This robot transfer unit supports their self-programming algorithms; it must be easy to set up, operate, and maintain. Abrasive debris and factory dust cannot stand in the way.

INDUSTRY: Manufacturing - Robotics

PRODUCT USED: LoPro 7th Axis

What is a Robot Transfer Unit?

Robot positioning systems (7th axis or Robot Transfer Units) provide flexibility in manufacturing and industrial spaces. For example, they may allow one robot to reposition between work stations to do the work of several robots. They may also extend a robot’s working area without need for a larger arm. Sometimes, the transfer of units away from the operating zone permits safe movement of workers or large equipment.

These motion systems are common in aerospace, automotive, warehouse, and manufacturing applications. Both traditional and collaborative robots can benefit from Bishop-Wisecarver’s 7th axis motion solutions, regardless of their size.

Why Bishop-Wisecarver?

Bishop-Wisecarver specializes in motion solutions that are expertly designed and delivered to perform, from a company you can trust.

Our solutions deliver maximum environmental and debris resistance. This ability to excel in harsh and extreme conditions is especially critical for drilling, welding, painting, etc.

Additionally, BW systems are specifically design by our motion experts to minimize your installation effort and maintenance costs. Many solutions require no maintenance over the planned life of the machine. (Click here to read more about the total cost of ownership advantage of our products.)

We don’t just deliver quality products; we deliver a Signature Experience™ to our customers. Bishop-Wisecarver’s expert application engineers can help you select the complete 7th axis system solution that is right for you, including motors and controls. Our team can also partner with you to design a fully customized system that meets your application requirements.