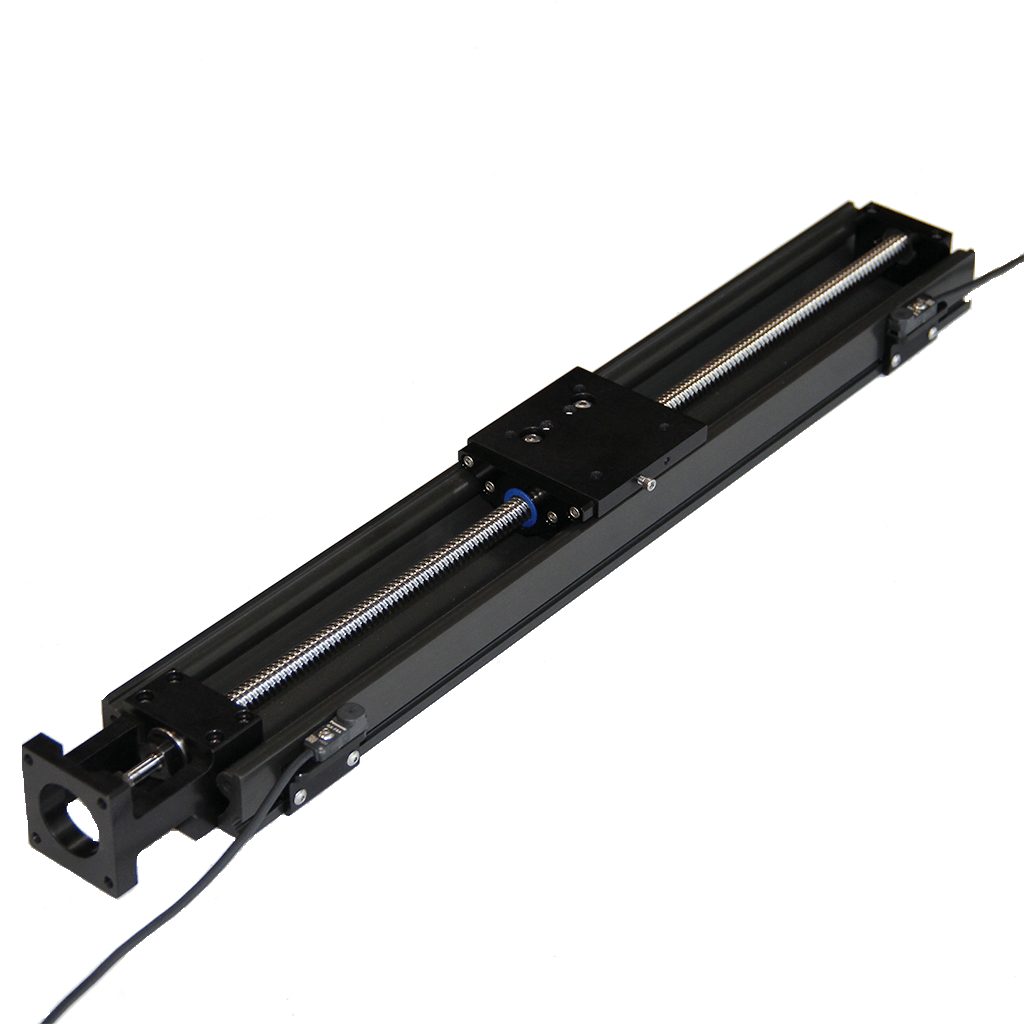

ECO60™ Linear Actuator

Chat with us to learn more about this product.

- Product Info

- Specification

- Success Stories

- Videos

- Faqs

- Reviews

ECO60 Innovative Redesign

- Time-saving linear actuator design

- Out-of-the-box turn-key motion axis with stepper motor and driver packages

- Simple carriage preload adjustment for customized feel

- Faster and easier motion system assembly

- Easy to repair and replace service parts

- Painless limit sensor position adjustments

- Versatile mounting options

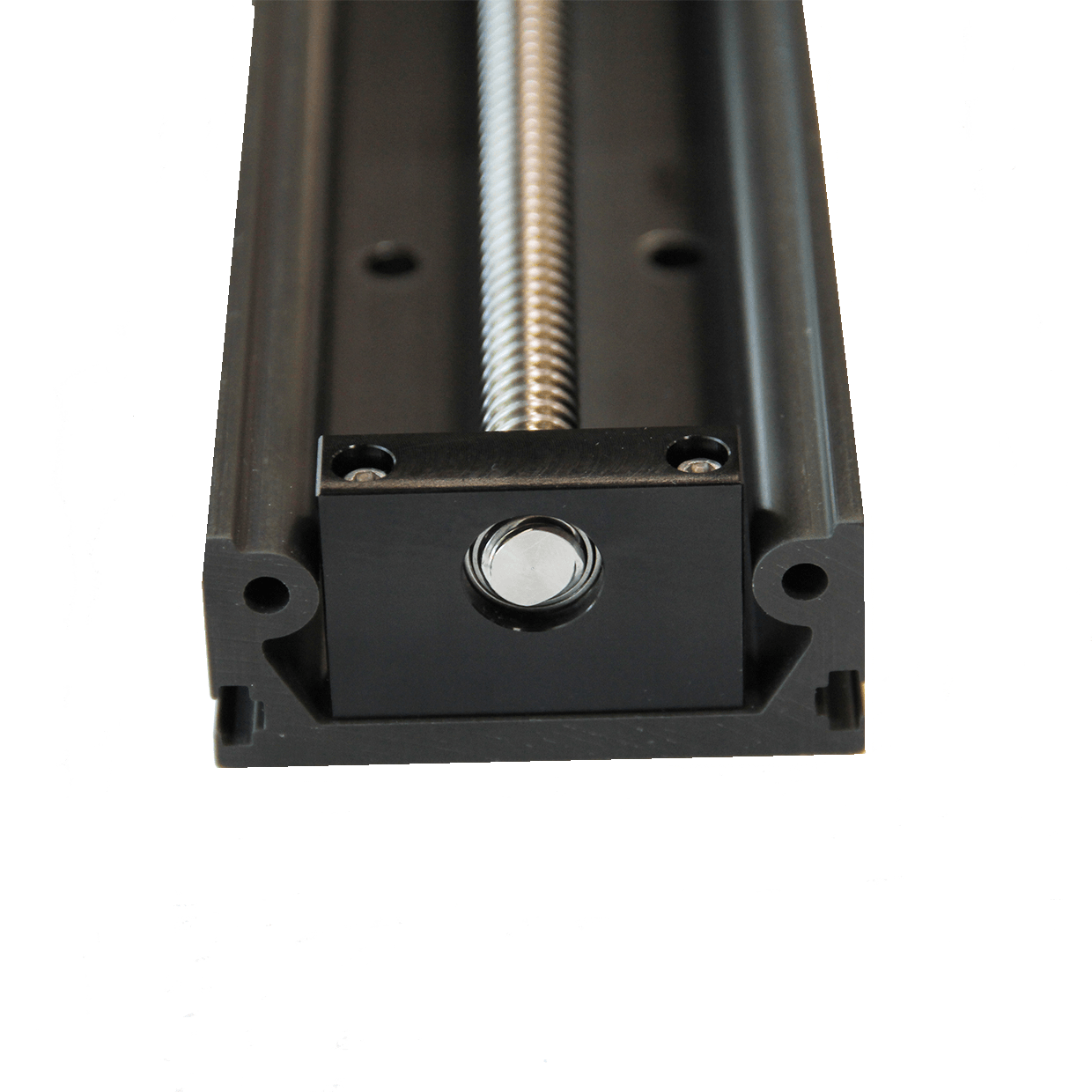

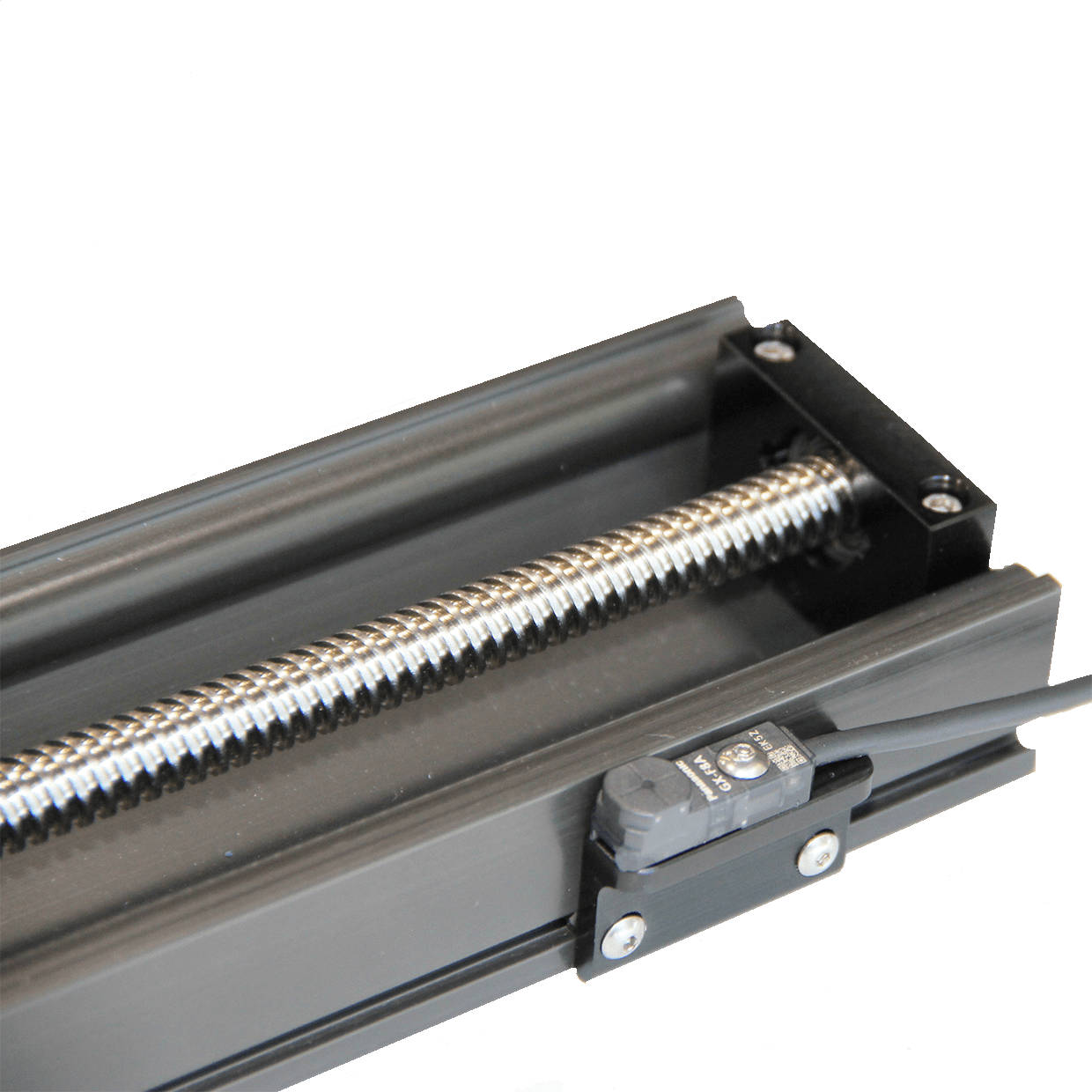

Innovative Base Extrusion

- Lower cost linear base extrusion is a single-piece design

- Position limit sensors anywhere along the T-slots on either side of the base

- Strong and compact design with linear guide surfaces

- Durable and recyclable 6061-T6 aluminum with hard anodize finish

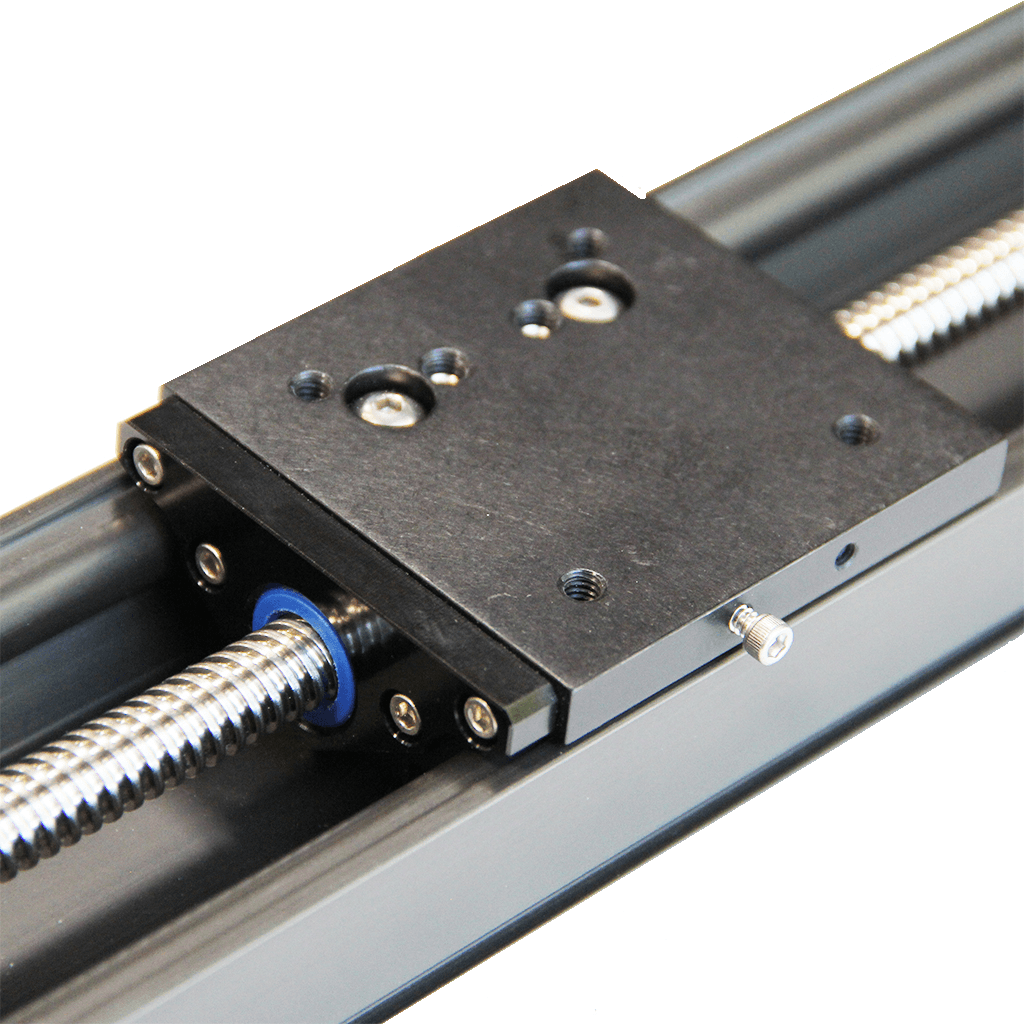

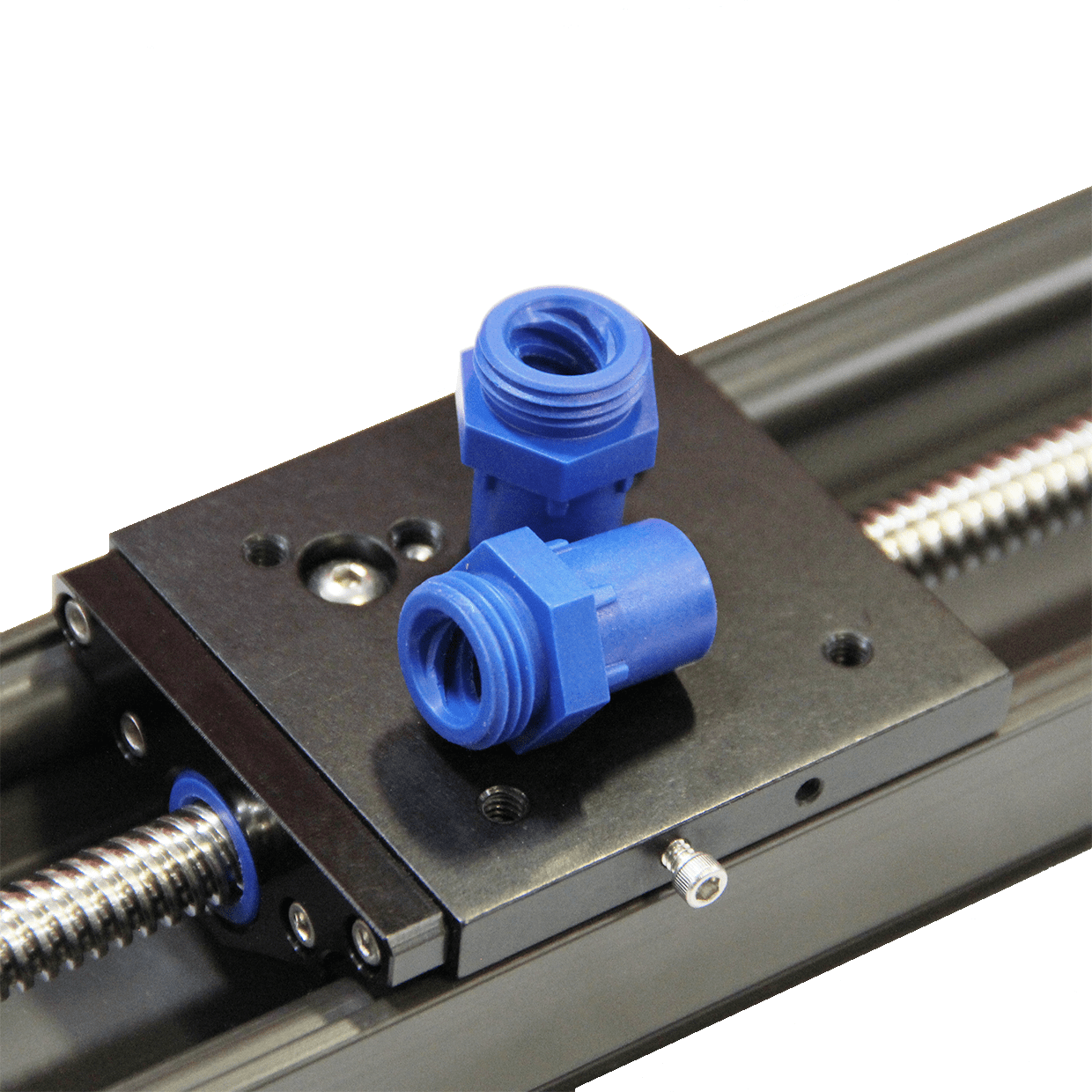

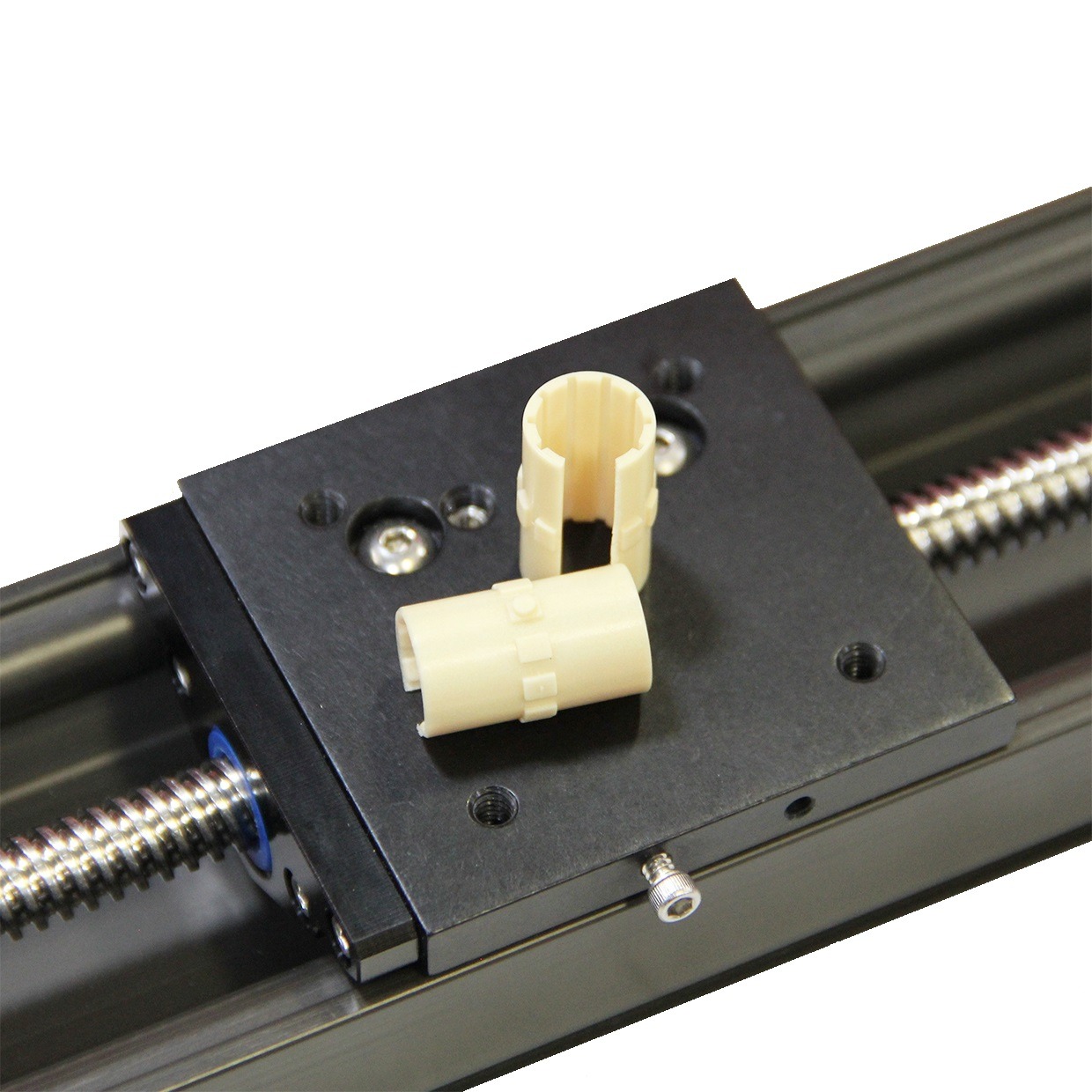

Improved Carriage Design

- Hassle-free preload adjustment to the linear base tube

- Fast and easy service with replaceable bearings and liners

- Simplified travel sensor flag is common screw hardware

- Wide and strong mounting hole attachment points on carriage

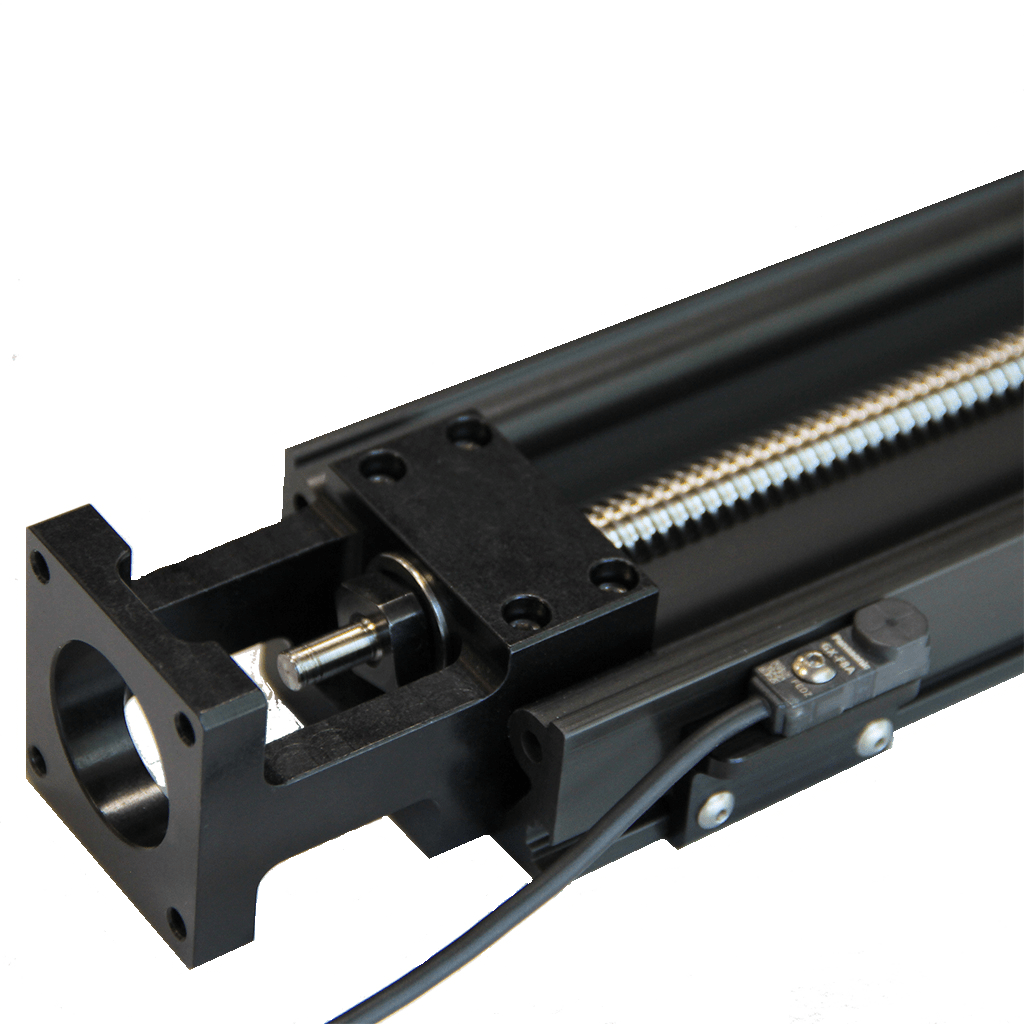

Integrated Motor Mount

- Reduced parts count and complexity with integrated motor mount

- Easy motor attachment designed for NEMA 17 motor frames

- Increase the performance with optional NEMA 23 adapter flange

- Complete your project faster with motor-ready mount

Lead Screw Drive Elements

- Fully assembled and adjusted lead screw drive elements

- Simple idler bearing on the lead screw for stability over long lengths

- Higher thrust or faster speed with your choice of lead screw pitch

- Serviceable and replaceable with low cost bearings and lead screw nuts

Travel Limit Sensors

- Safe and crash-free operation with optional home and travel limit sensors

- Fine-tune your travel stroke with attachment anywhere along the base T-slot

- Compact and low-power non-contact sensors with LED visual indicators

Repair Kits for Service

- Keep it running longer with easy to replace service parts

- Lower cost to repair your existing actuator than to purchase a new one

- Save time and stress with readily available replacements

Multi-Axis Gantry Attachment

- Quickly and easily attach into multi-axis configurations

- Low complexity assembly with simple gantry plates and hardware kits

- Save design time and effort with pre-engineered motion solutions

ROBUST FILTER CLEANING MACHINE

How automation is saving the environment - one diesel truck at a time!

THE CHALLENGE:

The traditional way to clean DPFs has always been to bring them to a facility that bakes them at 1150˚F for 12 hours. The problem however, is they can only be cleaned 3-4 times before the high heat cracks and breaks apart the ceramic parts of the filter. When this happens, the filter must be replaced at a hefty cost of $3-7K.

INDUSTRY: Automotive

PRODUCT USED: ECO60

Linear Actuator

The Signature Motion linear actuator series includes several lines from an economy line all the way up to high performance.

Where are ECO60 actuator products manufactured?

ECO60 actuators are produced at BWC headquarters near San Francisco, California, USA.

What materials are ECO60 actuators made from?

ECO60 is mostly aluminum in construction and made from 6061-T6 and 6063-T6 grades. The fastener hardware is all stainless steel including the lead screw and support bearings. The lead screw nut and sliding element linear bearings are made of plastic polymers.

Why is the carriage preload adjustment feature a benefit?

The ability to adjust the carriage preload is a benefit to end-users because it enables an application specific "feel" or "tune". The adjustment can be loose for less friction and lower wear rates, but a decrease in accuracy with additional carriage rock. A tighter adjustment will have more friction and higher wear rates, but improved accuracy and reduced carriage rock. Adjustments can be made periodically during the life of the actuator to compensate for wear in the bearing elements.

How much additional protection does the dust cover option provide?

The dust cover provides protection from debris falling onto the ECO60 from above. The sides remain open and exposed because of the design of the moving carriage. The dust cover is not effective when the actuator is mounted on the side. The cover does not have an ingress protection rating (IP rating), but if it did, it would be around an IP10 or IP20.

What fasteners are recommended for mounting ECO60?

The base of ECO60 has through hole and counter bore features to accomodate either 10-32 or M5 fasteners. Low head cap screws or button head cap screws in stainless steel are recommended.

How do I replace worn parts, or disassemble my ECO60?

There is a guide for how to properly disassemble an ECO60 and install the replacement parts that are provided in the repair kit. Contact BWC application engineers for this documentation.

How can I determine if ECO60 will work for my application?

Contact BWC application engineers for free technical advice on your application.