DualVee Single Edge Track

- Linear guide track with single 90° vee surface

- AISI 1045 carbon steel or AISI 420 stainless steel

- Available conditions include soft or hardened

- Drilled through holes for easy installation

- Mounting shoulder for accurate positioning of vee way

- Provided polished and oiled

- Product Info

- Specification

- Success Stories

- Videos

- Faqs

- Reviews

DualVee Linear Guide Track with Integrated Mounting Shoulder

BENCHTOP IMMUNOANALYZER

Providing Smooth Operation in a Compact Profile for Medical Equipment

THE CHALLENGE:

A manufacturer of desktop analyzers required a compact and reliable method of positioning and scanning the testing kit trays. The trays extend to provide easy access for the user to add samples to the reagent kits, then get drawn into the analyzer during operation. The reagent kits are scanned using a moving scanner head, which also required guided motion.

INDUSTRY: Medical

PRODUCT USED: DualVee Wheels and Track

MELON CUTTING AUTOMATION

Guide Wheels and Track for Food Grade and Washdown Environments

THE CHALLENGE:

Our customer required a solution to streamline and automate their melon cutting, and opted to use a reciprocating guillotine. The blade had to travel linearly a total of 180,000 inches per day in high-cycle operation. Any components used to guide this motion must be food grade, non-corroding, and suitable for a washdown environment.

INDUSTRY: Food and Agriculture - Cutting

PRODUCT USED: Stainless Steel DualVee Wheels and Track, Washdown Series Guide Wheel

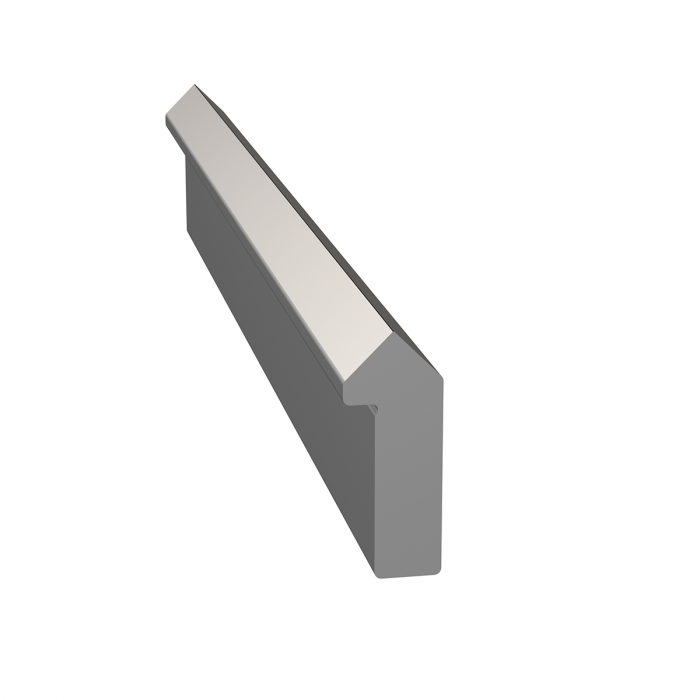

DualVee Overview

Motion Technology

V Bearing Guide Wheels

A Robotics Application Story

DualVee & GV3

Welding Application Story

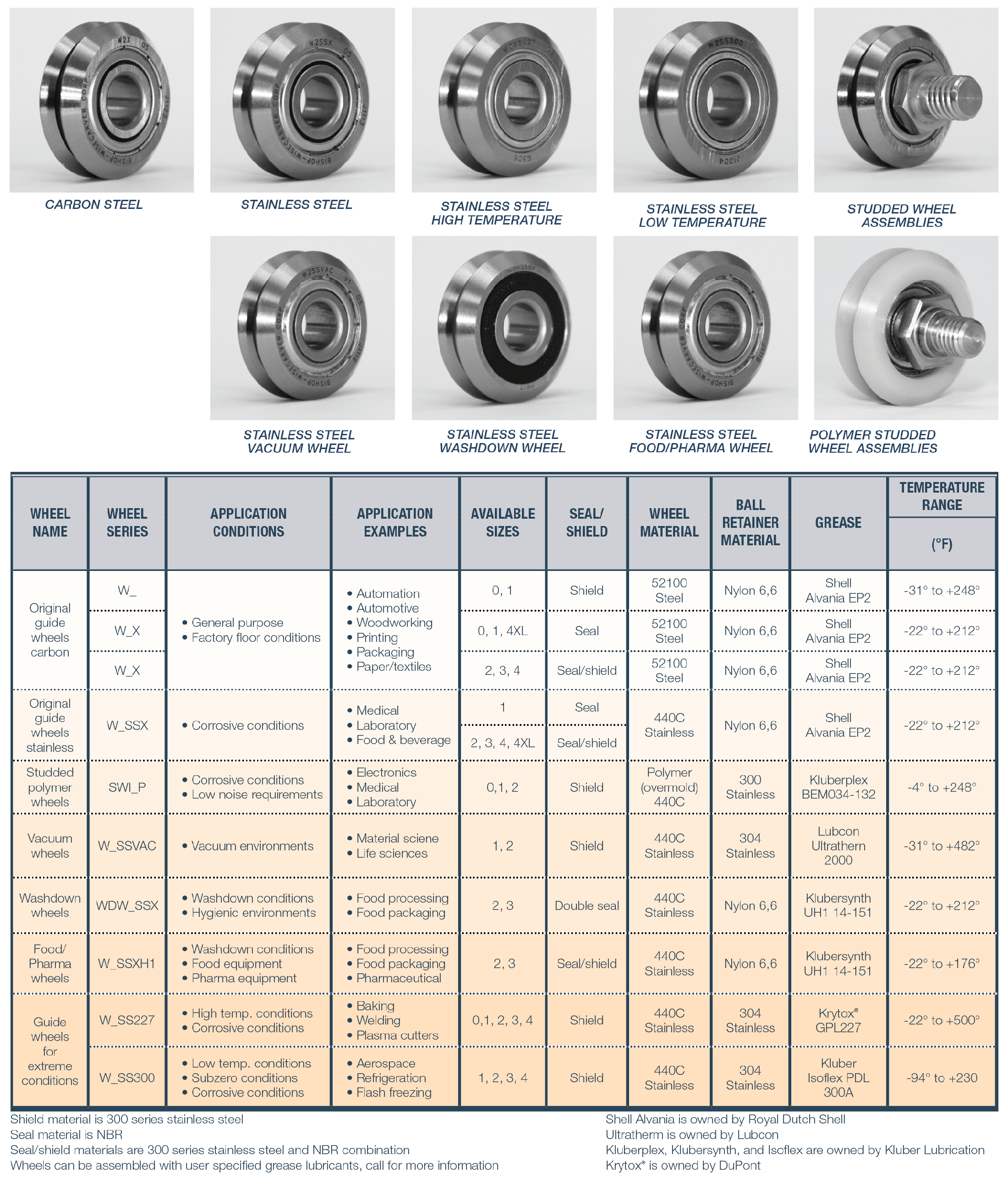

Are DualVee wheels available with a special grease?

Yes, we can fill the wheels with customer-specified or customer-supplied lubricants.

Can DualVee wheels be used with Hepco track?

In most cases, no. Almost all Hepco track uses a 70° vee, while DualVee wheels are a 90° vee. We do not recommend using 90 degree wheels on 70 degree track nor vice versa, because the contact surface between the wheel and track is very small. The smaller contact surface will accelerate wear and decrease system life.

Will DualVee wheels run on surfaces other than DualVee track?

DualVee wheels can run on any 90° surface, such as a piece of angle iron. However, note that wear characteristics will be different, and life might be compromised.

Can larger wheels run on smaller track?

In some cases, yes. There are instances where the larger wheels will not work. Consult the factory for details. Can smaller wheels run on larger track? Yes. The larger track may be used to provide more support for the machine.

Is double edge track available in other than size 0?

DualVee double edge track is available only is size 0. Hepco's GV3 line offers various double edge track sizes.

Does DualVee track need to be lubricated?

It is not necessary to lubricate the track in certain cases (light loads, low duty cycle), but a significant improvement in track life will result from lubricating the track with oil.

Where can I find information on mounting DualVee track?

Click here for mounting instructions. What is the maximum recommended speed for DualVee guide wheel technology? Speeds up to 5.5 meters per second.

Can guide wheels be used in high temperature applications?

Specially designed guide wheels using all stainless steel components, heat stabilized material, with special grease, can operate up to 500oF.

What is the temperature range of the standard carbon wheels?

The temperature range of standard carbon steel wheels is limited by the service temperature range of the elastomeric seal and grease. For standard grease, the service temperature range would be from -35oC to +100oC.

Is the grease used in polymer wheels the same as carbon wheels?

Yes. The same standard grease is used for both polymer and carbon wheels.

How much quieter are polymer wheels than carbon wheels?

Unknown. No quantitative data is available at this time.

Should the mounting threads for the eccentric wheels be secured with Loctite?

Yes. Use red Loctite if there is no future need to adjust the preload, and blue Loctite if future adjustments may be needed. However, when applying Loctite compounds, be sure to adjust and set the wheels within a short time after applying the compound.

Where can I obtain specifications for tightening the eccentrics?

Click here for instructions for tightening eccentrics. Note that the process is based on feel, rather than any quantitative tightening load.

What is the coefficient of friction for guide wheel technology?

Between 0.005–0.02, when operated on DualVee track.

What are the differences between the Studded Guide Wheels Assembly (SWA) and the Studded Integral (SWI) wheel?

The SWA wheel is an assembly where the stud is swaged onto the wheel. SWI wheels sizes 0 and 1 are swaged assemblies, sizes 2+ are fully integrated assemblies (stud is integrated with the inner race). The stud geometry and materials are also different between the SWA and SWI studded wheels. SWI concentric and eccentric studs feature different geometry to eliminate the wheels from being misassembled in the wrong location. SWI wheels are available up to size 4. SWA wheels are available up to size 2. DualVee wheels have a 90° vee while Hepco GV3 wheels have a 70° vee.

Are there benefits to the different vee designs?

Theoretical benefit #1: When the wheels are loaded, the highest stress occurs at the apex of the inner vee. The 90° vee in DualVee wheels creates a lower stress concentration at the apex than the 70° vee (assuming identical apex relief radius) and also results in less of a resultant "outward wedging force" on the wheel.

Why is the stainless steel track magnetic, and why does it rust?

DualVee track is made from type 420 martensitic stainless steel. This alloy can be heat treated to produce a hardened track surface, which provides good wear resistance in service. Martensitic alloys are magnetic in all heat treatment conditions, which relates to the ratio of iron/chromium contents within the chemical compositions of the alloys.It has been observed that stainless steel track can rust in service. However, all grades of stainless steels can rust in certain environments, but some are more corrosion resistant than others. For example, austenitic stainless steels (300 series) are accepted as having the best corrosion resistance of all stainless steel alloys. The lower corrosion resistance of type 420 can be attributed to a lower chromium content than 300 series stainless steels. It is important to note that while 300 series stainless steels are the most corrosion resistant alloys, they are not hardenable by heat treatment. This inability to harden means that 300 series stainless steels are not as suitable for track applications and will not perform as well as 420 series in abrasive wear environments.

What do the terms 'axial load' and 'radial load' refer to with regard to a bearing?

Axial load is any load that is parallel to the axis of rotation of the bearing. Radial load is any load that is perpendicular to the axis of rotation.

What does the term 'Double Row Angular Contact' refer to with regards to bearings?

"Double row angular contact" refer to the two rows of ball bearlings loaded at a particular angle. These bearings offer high load carrying capacity in both axial and radial directions. These high load capabilities result in long service life.

Why does the DualVee wheel have an inherent self-cleaning property as it rolls along its mating track?

DualVee Motion Technology is designed for dirt and extreme environments. The patented 90° DualVee guide wheel design creates a velocity gradient because the circumference of the wheel is greater at the major diameter than the minor diameter. This velocity gradient causes a constant sweeping action, thus cleaning debris from the track.

How do I calculate forces and life for DualVee guide wheels?

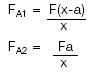

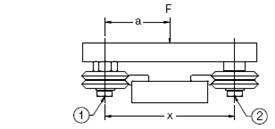

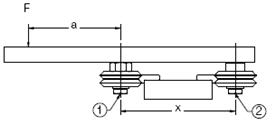

Step 1: Calculate loads on each bearing Given below are force equations for some common four-wheel carriage assembly configurations, in which two wheels absorb the load at both points 1 and 2, divide the calculated load by 2 to obtain the load on each wheel.

Scenario 1

Scenario 2

Scenario 3

*Note: Since carriages use four wheels, two wheels absorb the load at both points 1 and 2. Divide the calculated load by 2 to obtain the load on each wheel. Example: Scenario 3 L = 200 lbs X = 15 inches Y = 5 inches

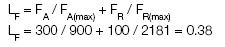

Step 2: Calculate the load factor for the most heavily loaded bearing Using the above example with size W4X guide wheel, FA(max) and FR(max) from the DualVee load rating chart.

Step 3: Calculate life estimate For life constants, AF assumed at 1