SteadyRail™ Linear Stages

Chat with us to learn more about this product.

- Product Info

- Specification

- Success Stories

- Videos

- Faqs

- Reviews

Overview

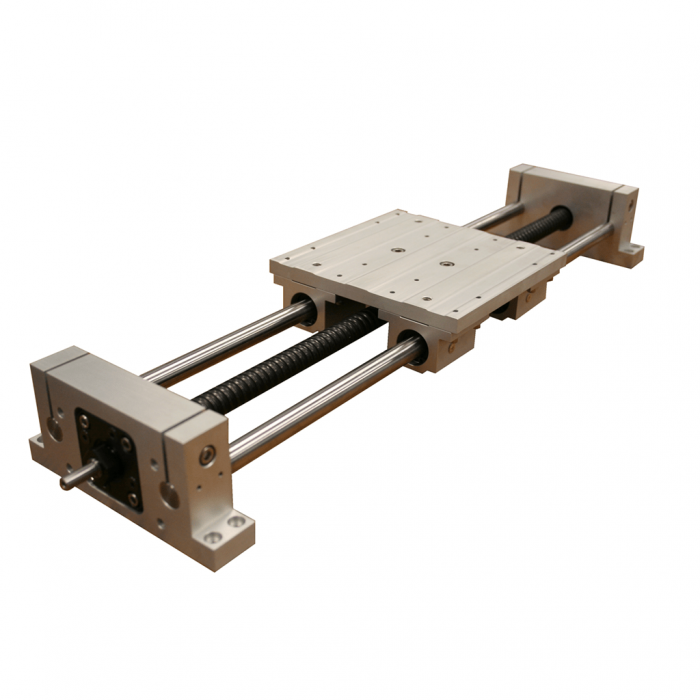

SteadyRail uses round shafting and ball bushings to provide smooth, low friction motion. With an emphasis on simplicity and durability, SteadyRail is available in several different stages and versions making it a motion solution that can do it all. Use SteadyRail as an undriven linear guide or as a ball screw driven linear actuator with the easy attachment of a NEMA 23 or NEMA 34 motor. Save design time and simplify your supply chain with pre-configured SteadyRail motion systems that have standardized hole patterns for mounting and attaching.

SteadyRail comes standard with self-aligning pillow block bearings in several different sizes as well as in several different support options. Each size includes either single or double wide pillow blocks in a standard series for simple installation, adjustable series with adjustable clearance, or the open series for long stroke applications. Additionally, SteadyRail is available with four different end support systems including end supported, continuously supported, double end supported, and double continuously supported.

Low maintenance

Added drive components for standalone functionality

Ball screw drive mechanisms integrated

Available as a complete motion system

Low coefficient of friction at 0.003 typical

Options

Travel ranges from 6" to 42" stroke length

Unsupported or continuously supported round shaft linear bearings

Carbon or stainless steel shafting in several diameters and load capacities

Undriven or with ball screw drive mechanisms with various diameters and lead pitch

Motor mount flanges and shaft coupler combinations

Precision machined and anodized aluminum components

Control Packages

BW can supply complete and affordable linear motion systems. The continuously supported 3B systems can be supplied with stepper motors, servo motors, controllers, drives and even an HMI user interface. We use standard motor mounting configurations for these continuously supported systems. Call our Application Engineering team to discuss your requirements.

For motor options, contact 925.439.8272 or info@bwc.com.

ULTRASONIC CAKE CUTTER

High-throughput, High-reliability Cutting of Frozen Food

APPLICATION DESCRIPTION:

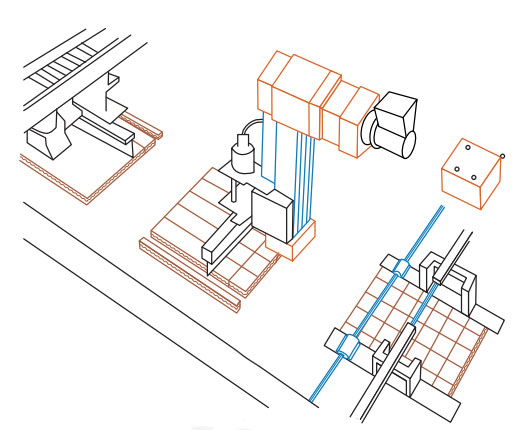

Two ultrasonic vibration blades are actuated in order to slice frozen cake into a grid when it passes on a conveyor. Each is mounted to an XZ gantry which uses Hepco PDU2 actuators. These belt-driven systems can operate at up to 6 m/s for high- throughput applications and come in a corrosion-resistant variety.

INDUSTRY: Food - Cutting

PRODUCT USED: SteayRail and PDU2

Linear Actuator

The Signature Motion linear actuator series includes several lines from an economy line all the way up to high performance.