HepcoMotion DTS2 – High Speed Driven Track System

The DTS2 High Speed Track System has been developed for high-speed and rapid indexing applications. Load bearing carriages are driven smoothly around a closed circuit, using a scroll drive for positional accuracy and strong driving force. The track is configurable into nearly any shape made from straight and curved sections, providing maximum design flexibility.

Chat with us to learn more about this product.

- Product Info

- Success Stories

- Videos

- Faqs

- Reviews

Strong Drive.

DTS2 carriages can accept high driving forces (much higher than DTS). They are linked by extremely strong steel cables encapsulated in a polyurethane toothed belt.

Smooth Motion.

The speed of the carriages is the same on the curved segments as it is on the straights, resulting in a smooth motion. The carriages on the curved sections of the original DTS move faster than those on the straight sections, so the carriages experience a pronounced acceleration at every joint between the straight and curved sections.

High Speed.

The smooth motion, uniformity of carriage speed and inherent balance of the DTS2 make it suitable for high speed use. Constant linear speeds of 3m/s are possible.

Rapid Indexing.

The speed and strength of the drive means that the DTS2 is well suited to indexing applications with high accelerations.

Good Positional Accuracy.

The precision straight and curved slides ensure that carriages are guided to a high degree of precision. The drive provides rigid positioning along the track and repeatability of ±0.2mm depending on system size. The pitching of carriage along the straight sections is held to similar tolerances. Applications requiring even better accuracy may be satisfied by the addition of an auxiliary carriage locking system.

Broad Range of sizes.

Standard designs provide typical working loads of up to 40 kg (approximately 88 lbs.) per carriage. The operating principle is easily applied to larger systems, including the Hepco HDRT (Heavy Duty Track System) which has much higher load capacity.

Stainless Steel Version.

The DTS2 is available in stainless steel, with all track, bearing, springs and fasteners in stainless steel. Carriages will normally be made in aluminum alloy with a food compatible corrosion resistant coating.

Simple & Compact.

There are fewer components in the DTS2 than in the earlier DTS design, making the new product simpler and much less deep than its predecessor. Flexible Configuration. The DTS2 track can take nearly any shape made with straight and curved sections. The curved slides must be of a single radius, there must be no "~" bends, and at least one straight section must be over a minimum length to accommodate the drive.

LIQUID DETERGENT PACKAGING

Space Efficient, Low Maintenance Packaging System

APPLICATION DESCRIPTION:

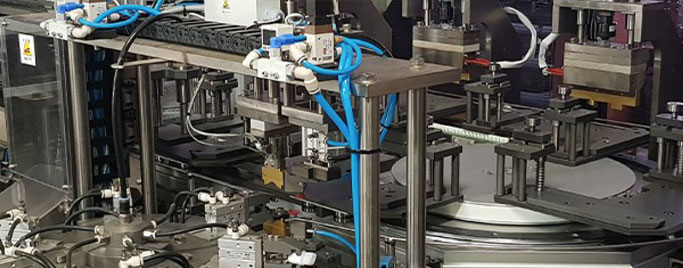

When South Korean automation manufacturer New Hanil Engineering was commissioned to develop a machine to fully automate the production of liquid detergent packaging, it was essential to build a space-saving, low maintenance system that would provide the high throughput required. The machine produces spout pouches, one of the fastest growing packaging formats that offer a flexible, cost-effective alternative to plastic bottles. At the core of the machine, New Hanil required a precise and reliable carousel system to guide and transfer the spout packs around the system between the different processes.

INDUSTRY: Automation - Packaging

PRODUCT USED: DTS Driven Track System

High Speed Track System

Packaging and Assembly

Scroll Driven Track System

High speed and Rapid Indexing