XLA™ Linear Actuators

- Ultra High Load Capacity, Compact Size

- Ball Screw Drive and Profile Rail Linear Guides

- Low Coefficient of Friction

- Solid and Stiff Construction Materials

- Precise and Repeatable

Chat with us to learn more about this product.

- Product Info

- Specification

- Success Stories

- Videos

- Faqs

- Reviews

Overview

The XLA Linear Actuators are the most robust of all standard Signature Motion stages to date! There are two standard frame sizes including the XLA 9 and the larger XLA 15.

The XLA actuators were designed as standalone Y-axis motion stages for gantry applications and they are extremely rigid, eliminating the cost of structural support over longer spans. They are constructed for a wide variety of applications requiring ultra-high capacity in a compact envelope and can provide exceptional structural strength even when used without support. The linear profile rail guides and ball screw drive mechanism provide very accurate and repeatable motion.

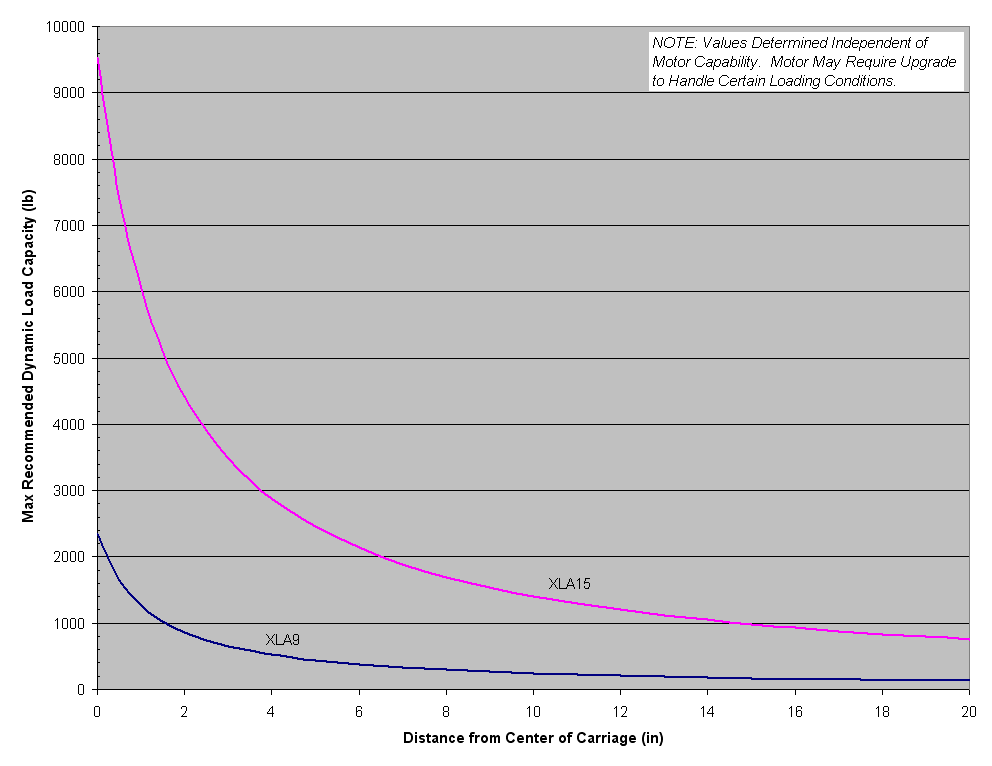

The XLA 9 has a static capacity exceeding 3,500 lbs. and a dynamic capacity of more than 2,300 lbs. based upon 2 million inches of travel life in a unit with an envelope of 1.99" tall and 3.75" wide.

The XLA 15 has a static capacity exceeding 14,000 lbs. and a dynamic capacity of more than 9,500 lbs. based on 2 million inches of travel life in a unit with an envelope of less than 3" tall and 6" wide.

Moment Load Compensation negates the effects of applied moment, instead making offset loads into an equivalent vertical load. Moment Load Compensation makes slide life easy to calculate and consistent.

The actuator travel length can be specified in any 1" increment. The XLA 9 has a minimum stroke of 3" and a maximum stroke of 34" while the XLA 15 can be between 3" minimum and 99" maximum. Custom length XLA 15 actuators have a theoretical maximum length of 110" and can be manufactured under close Bishop-Wisecarver engineering support. Excessively long travel lengths require very long unsupported ball screws and screw whip vibrations will limit the maximum attainable speed.

The actuator travel length can be specified in any 1" increment. The XLA 9 has a minimum stroke of 3" and a maximum stroke of 34" while the XLA 15 can be between 3" minimum and 99" maximum. Custom length XLA 15 actuators have a theoretical maximum length of 110" and can be manufactured under close Bishop-Wisecarver engineering support. Excessively long travel lengths require very long unsupported ball screws and screw whip vibrations will limit the maximum attainable speed.

Rigid Construction

The XLA actuators are built using compact T-slot aluminum extrusions that are designed to provide exceptional structural strength even when used without support. The XLA series is seen as a solution to cross-axis applications where the rigid extrusion enables the actuator to become a structural member of the machine without the need for expensive base mounting structures. This feature makes the XLA perfect for a cross-axis, or Y-axis, on gantry applications.

The XLA actuators are built using compact T-slot aluminum extrusions that are designed to provide exceptional structural strength even when used without support. The XLA series is seen as a solution to cross-axis applications where the rigid extrusion enables the actuator to become a structural member of the machine without the need for expensive base mounting structures. This feature makes the XLA perfect for a cross-axis, or Y-axis, on gantry applications.

Adaptable

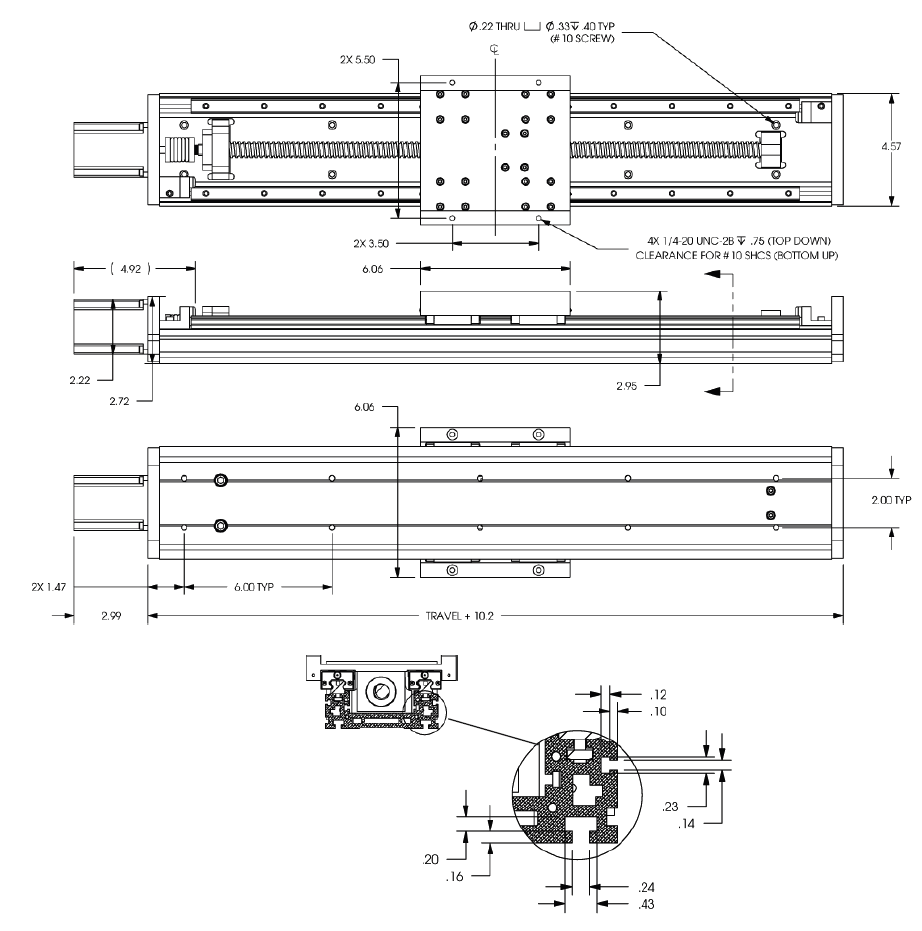

All XLA series products incorporate T-slot channels along the full length of the base. This bilateral channel allows for quick and easy adjustment of limit switches and other peripheral add-ons. The channels located on the underside of the base are configured to allow for simplified mounting into an X-Y configuration. Multiple axis units can be easily joined without the need for additional mounting plates. The mounting holes in the XLA carriage match mounting holes in the XLA base. The XLA can be mounted in X-Y and Z configurations with the optional Z bracket.

All XLA series products incorporate T-slot channels along the full length of the base. This bilateral channel allows for quick and easy adjustment of limit switches and other peripheral add-ons. The channels located on the underside of the base are configured to allow for simplified mounting into an X-Y configuration. Multiple axis units can be easily joined without the need for additional mounting plates. The mounting holes in the XLA carriage match mounting holes in the XLA base. The XLA can be mounted in X-Y and Z configurations with the optional Z bracket.

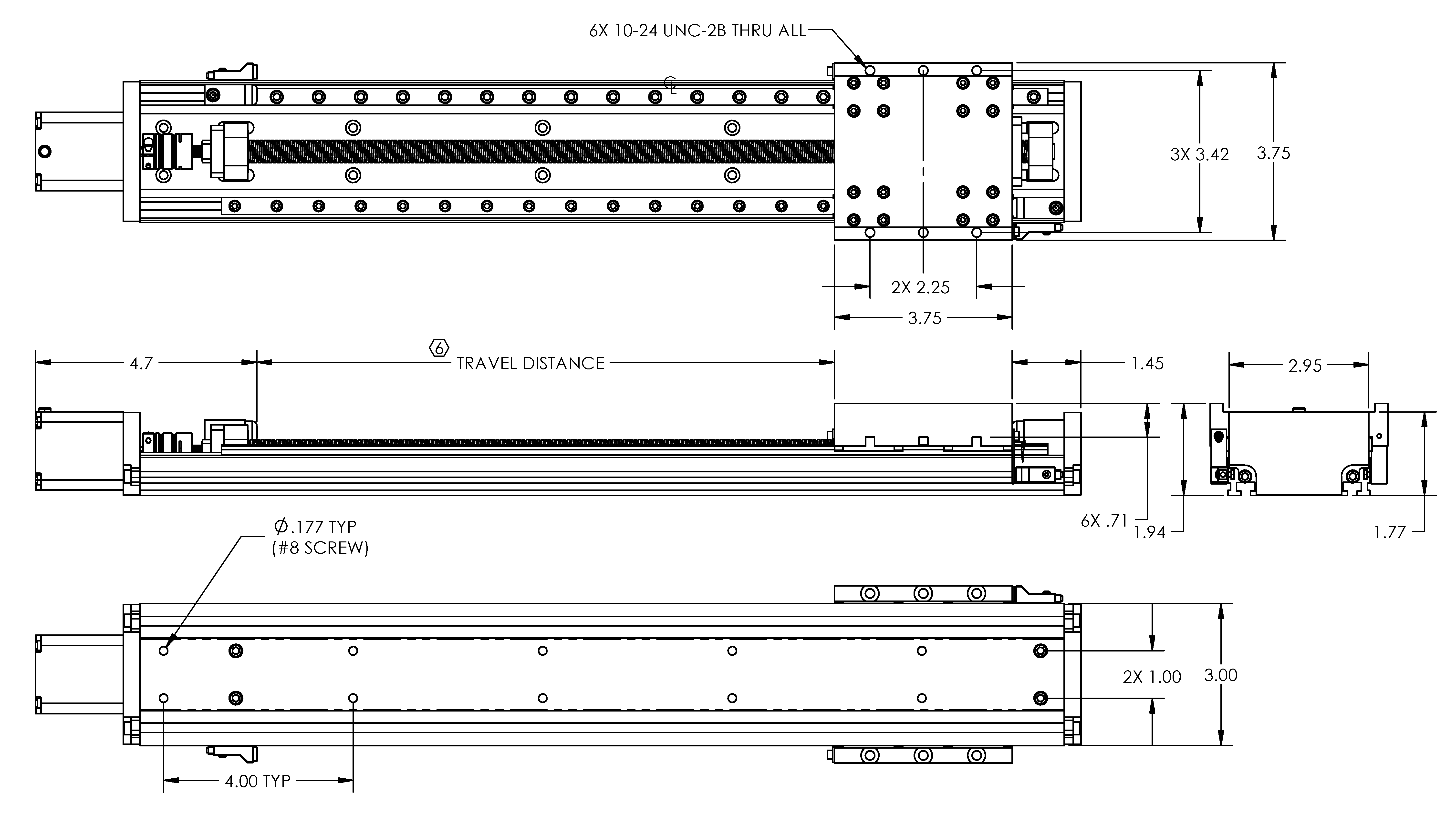

A close examination of the top carriage mounting pattern reveals a unique top-down or bottom-up mounting method to make attachment of your devices to the XLA a simple, versatile process.

Environmental Compatibility

The XLA actuators incorporate an anodized 6061-T6 aluminum base and are constructed with carbon steel screws, fasteners and components. Stainless steel options are available. Upon special request, XLA can be configured with a stainless steel ball screws, profile guide rails, and end support bearings for additional environmental corrosion resistance.

The XLA actuators incorporate an anodized 6061-T6 aluminum base and are constructed with carbon steel screws, fasteners and components. Stainless steel options are available. Upon special request, XLA can be configured with a stainless steel ball screws, profile guide rails, and end support bearings for additional environmental corrosion resistance.

5mm lead and 10mm lead options

Ball screw drive

Home and limit switches

XLA9 Dimensional Drawing

XLA15 Dimensional Drawing

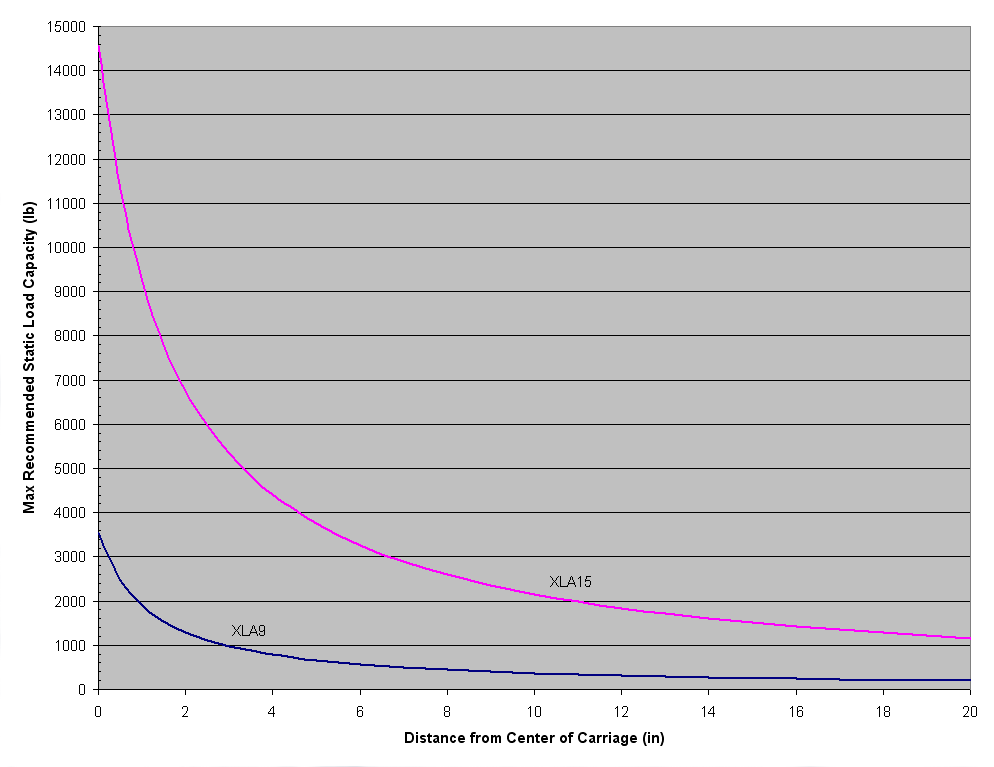

Load Capacity Ratings

Dynamic Load Capacity Chart

Statlic Load Capacity Chart

AERIAL PHOTOGRAPHY

Reliable Actuator Ensures the Best Aerial Shots Every Time

THE CHALLENGE:

An aerial photography systems manufacturer was contracted for a unique project. The goal was to affix a camera system to the fuselage of a modified Cessna 337 aircraft. The camera needed to extend below the aircraft during flight to catch unobstructed aerial pictures. Providing this extension and maneuvering, required a linear actuator that is able to

withstand the shock loads the aircraft is subject to during landing sequences.

INDUSTRY: Entertainment, Photography

PRODUCT USED: XLA 15 Linear Actuator

Linear Actuator

The Signature Motion linear actuator series includes several lines from an economy line all the way up to high performance.