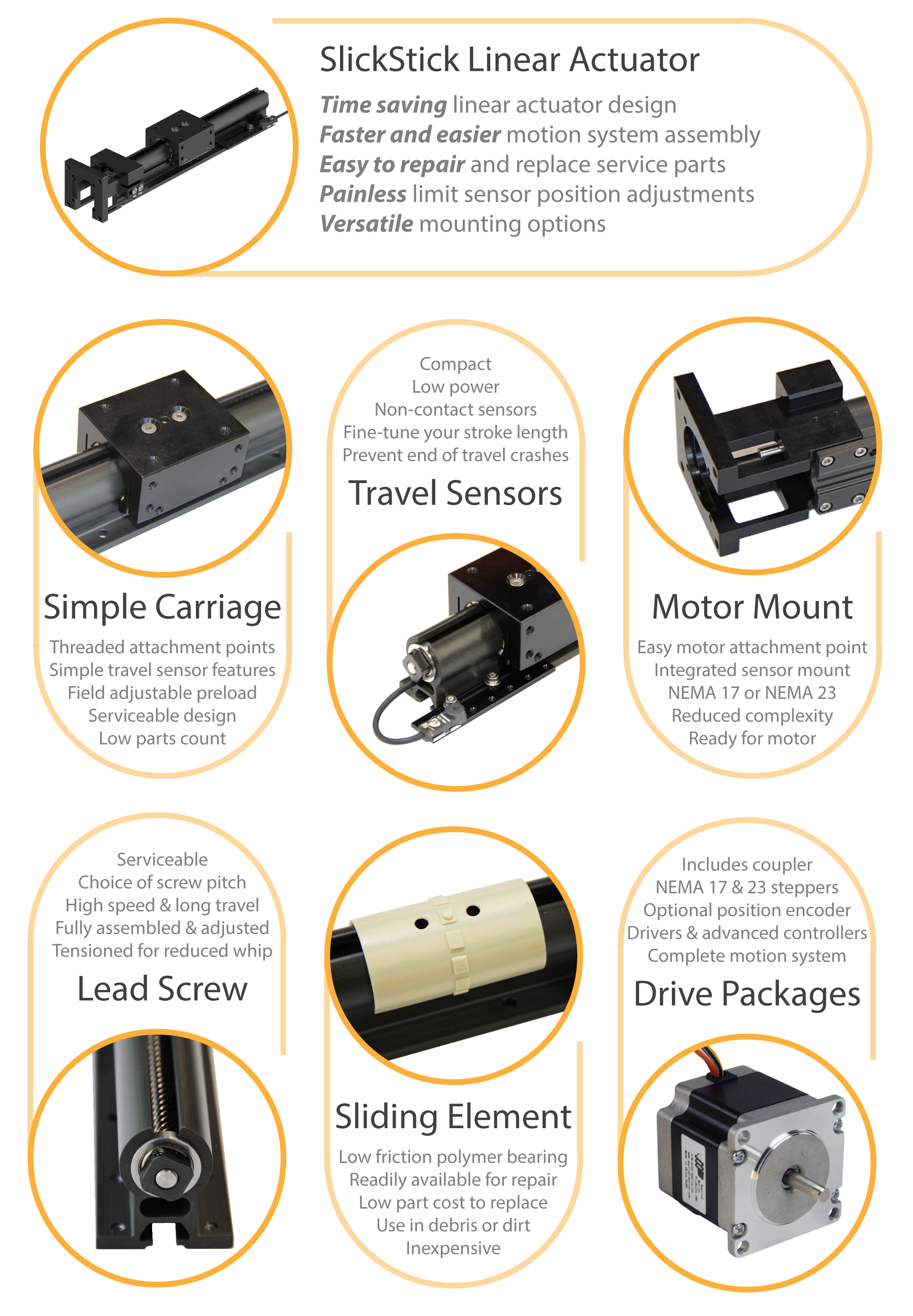

SlickStick™ Linear Actuators

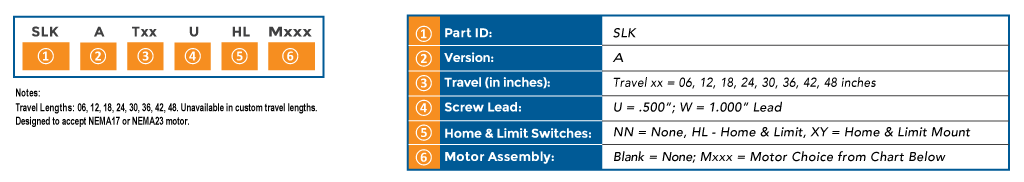

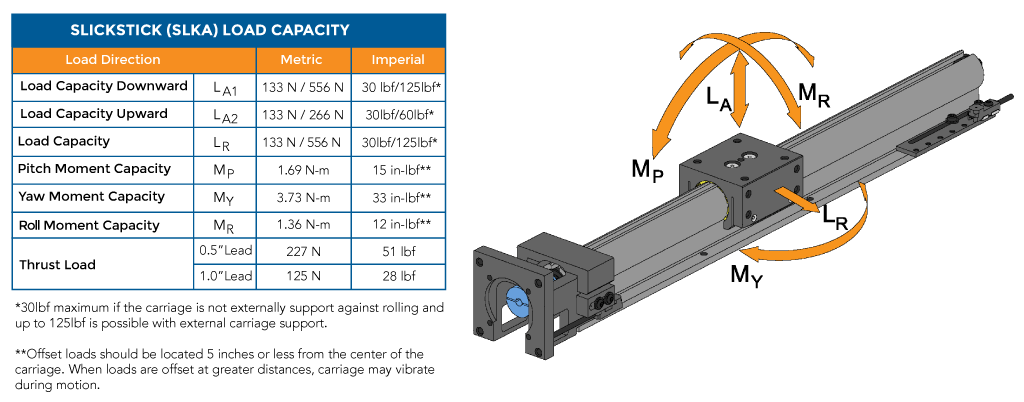

- Integrated motor mount accepts NEMA 17 or NEMA 23

- Standard travel lengths from 6 to 48 inches in 6-inch increments

- Lead screw driven with motorized packages

Chat with us to learn more about this product.

- Product Info

- Success Stories

- Videos

- Faqs

- Reviews

HIGH VOLUME COOKIE MANUFACTURING

Debris Tolerant, Low Cost, High Volume

THE CHALLENGE:

One of the main considerations with the cookie manufacturing application is distance. The actuator would need to be able to comfortably travel about

48 inches over the cookie conveyor belt. It would also need to be somewhat accurate in order to get the preserves centered properly on the sugar cookie. Because of the working environment the solution also needs to be debris tolerant, low cost and easily repairable.

INDUSTRY: Food Manufacturing

PRODUCT USED: SlickStick

Linear Actuator

The Signature Motion linear actuator series includes several lines from an economy line all the way up to high performance.

Where are SlickStick actuator products manufactured?

SlickStick actuators are produced at BWC headquarters near San Francisco, California, USA.

What materials are SlickStick actuators made from?

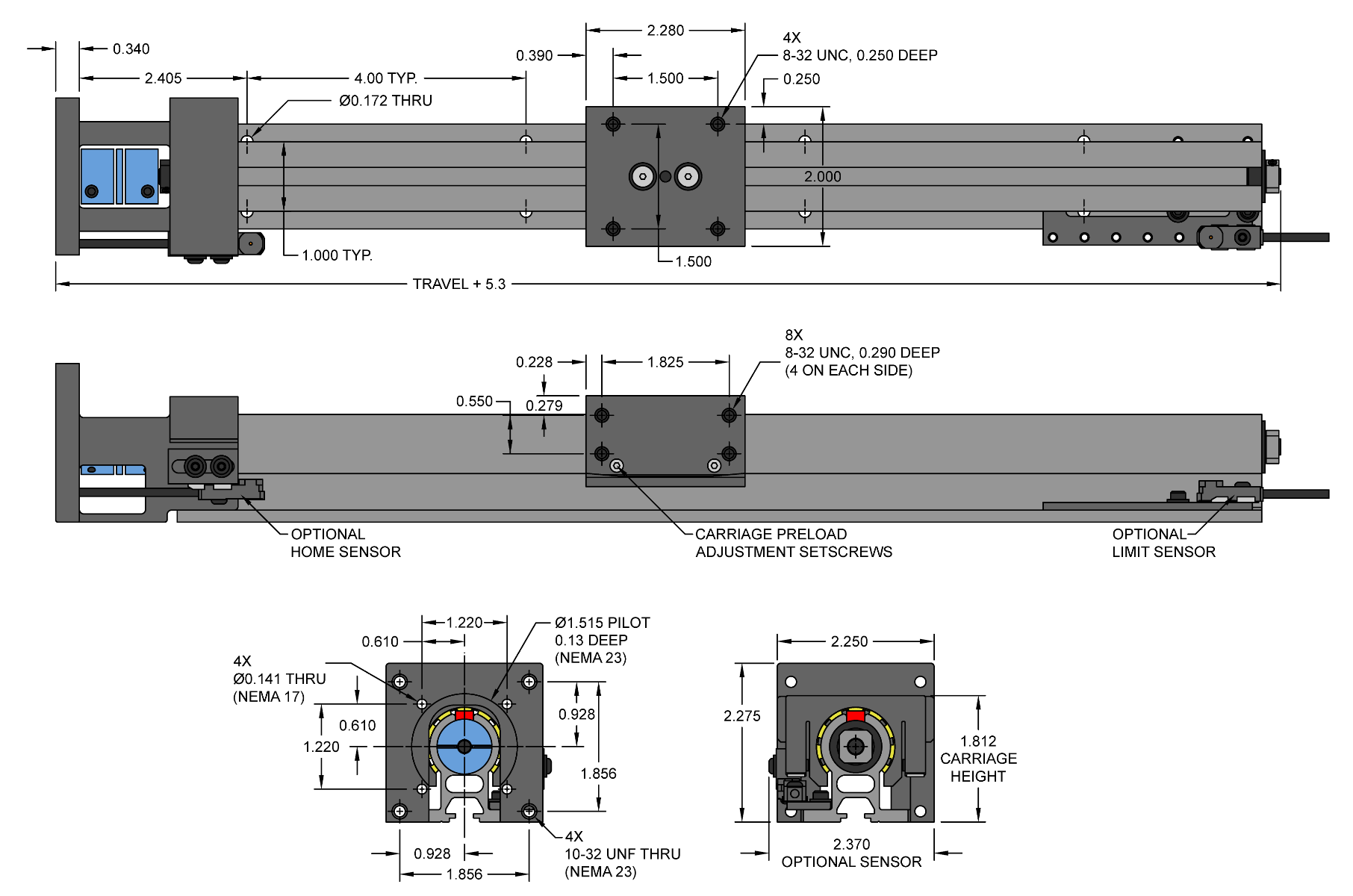

SlickStick is mostly aluminum in construction and made form 6061-T6 and 6063-T6 grades. The fastener hardware is all stainless steel including the lead screw and support bearings. The lead screw nut and sliding element linear bearings are made of plastic polymers.

Why is the carriage preload adjustment feature a benefit?

The ability to adjust the carriage preload is a benefit to end-users because it enables an application specific "feel" or "tune". The adjustment can be loose for less friction and lower wear rates, but a decrease in accuracy with additional carriage rock. A tighter adjustment will have more friction and higher wear rates, but improved accuracy and reduced carriage rock. Adjustments can be made periodically during the life of the actuator to compensate for wear in the bearing elements.

What fasteners are recommended for mounting SlickStick?

The base of the SlickStick has through hole and counter bore features to accommodate either 8-32 or M4 fasteners. Low head cap screws or button head cap screws in stainless steel are recommended.

How do I replace worn parts, or disassemble my SlickStick?

There is a guide for how to properly disassemble my SlickStick and install the replacement parts that come in the repair kit. Contact BWC application engineers for this documentation.

How can I determine if SlickStick will work for my application?

Contact BWC application engineers for free technical advice on your application.