LoPro® – Linear Actuator

LoPro linear actuators are an actuated linear motion system based upon proven DualVee guide wheel technology for smooth and quiet motion over long lengths. Actuation options include AT series belt, ANSI roller chain, lead screw, and ball screw. LoPro linear actuators are also available in a non-actuated version. LoPro linear actuators provide a tough, cost effective, low friction, low profile modular solution, built to withstand a wide range of operating environments. Complete systems include your preference of wiper or basic wheel plates, and may be mounted or un-mounted. Support beams are available in aluminum or steel to meet application demands and to provide ease of installation. A wide variety of gantry brackets are available to form complete LoPro gantry systems.

- Product Info

- Specification

- Success Stories

- Videos

- Reviews

Bishop-Wisecarver has recently updated the design for standard belt-driven and chain-driven LoPro systems. This includes a new option for open-bottom drive and idler ends, making it easier to dispel debris. For more information, please click here. Check out our Product Status Notification page for all product updates.

Overview

LoPro linear actuators are an actuated linear motion system based upon proven DualVee guide wheel technology for smooth and quiet motion over long lengths. Actuation options include AT series belt, ANSI roller chain, lead screw, and ball screw. LoPro linear actuators are also available in a non-actuated version. LoPro linear actuators provide a tough, cost effective, low friction, low profile modular solution, built to withstand a wide range of operating environments. Complete systems include your preference of wiper or basic wheel plates, and may be mounted or un-mounted. Support beams are available in aluminum or steel to meet application demands and to provide ease of installation. A wide variety of gantry brackets are available to form complete LoPro gantry systems.

Undriven Assemblies

In the most basic form, LoPro is available as a rigid and compact linear guide rail. Although it is designed as an actuator with drive mechanisms, LoPro sub-assemblies can be used as standalone linear guides. The linear bearing track plate assemblies can be constructed in very long lengths with carbon steel or stainless steel 90-degree vee guide track. Wheel plate assemblies with mating 90-degree guide wheel bearings can be used on the linear track plate guideways to create heavy load capacity linear bearings. The track plate bases are made from precision machined extruded aluminum and provide an accurate platform.

Belt-Driven Actuators

Belt-driven LoPro actuators are ideal for long travel lengths and high speeds. Belt drives feature AT-style reinforced polyurethane belting. Belt drive systems may be mounted to either steel or aluminum support beams and come with your choice of the wiper wheel plate or the basic wheel plate. Corrosion-resistant versions are available, as are multiple wheel plates.

Chain-Driven Actuators

Chain-driven LoPro actuators are available with standard or corrosion resistant ANSI roller chains. The chain driven LoPro is ideal for vertical hoisting and large load actuation over long travel lengths. Aluminum and steel support beams may be used to mount the chain drive. Other options include basic and wiper wheel plates, with or without multiple wheel plates.

Lead Screw Actuators

Lead screw -driven LoPro actuators feature either BY or NTBY lead screw nut types to meet your backlash requirements. Metric and inch screw leads are also available in lead accuracies to 0.0006 in/in (mm/mm). Lead screw actuators may be selected with steel or aluminum support beams and with your preference of basic or wiper wheel plates.

Ball Screw Actuators

Metric ball screw -driven actuators are accurate to 0.004 in/ft (0.1 mm /300mm). Ball screws are available in standard and corrosion-resistant materials to meet environmental constraints. Basic or wiper wheel plates may be selected, as well as steel or aluminum support beams.

Actuator Configuration Options

There are many possible design configurations of LoPro actuators and each actuator is made to specification from standard sub-assemblies and components. The system travel, or stroke length, must always be defined. The standard versions include your choice of carbon steel or stainless steel hardware and linear bearing elements. The belt- and chain-driven versions have several options for the drive shaft output side and include left hand output, right hand output, and dual shaft output. The dual shaft version is ideal for coupling a rigid shaft between two parallel actuators and driving the system with one motor. Please inquire with a BW application engineering for additional accessories such as travel limit sensors and sensor flags, optional tools, individual replacement parts, and other support products.

Wheel Plate Options

There are two choices for wheel plate assemblies - wiper wheel plates and basic wheel plates. Wiper wheel plates are available with your choice of DualVee guide wheels and provide the lowest height solution. Basic wheel plates are the more economical choice and come with studded DualVee wheels and your choice of either lubricators or wheel covers. Both the wiper wheel plate and the basic wheel plates are intended to run on track plate assemblies.

Support Beam Options

Support beams are available in an extruded aluminum beam or a structural steel beam. The extruded aluminum beam comes with T-slots for quick and easy mounting of brackets and other aluminum framing members. Steel support beams are made to ASTM A500 Grade A standards and provide a high modulus, making them a rigid mounting option.

Motor Mount Options

Our new line of motor mounts is designed to fit any manufacturer's motor or gearbox. Each motor mount is supplied as a kit, complete with shaft coupling and mounting hardware. Standard or custom mounting solutions can be provided within five days.

Open Bottom Drive/Idler End Options

Belt-driven and chain-driven systems now include the option to have the bottom of the drive and idler ends machined open, allowing for enhanced expulsion of debris from each of the ends.

Track Plate Assemblies

Track plate assemblies combine your choice of single edge DualVee track with an easy-to-mount aluminum base. The aluminum base is made from high precision anodized aluminum alloy. Track plate assemblies are easily butt-joined to provide infinite lengths.

Gantry Brackets

A wide variety of gantry brackets are available to form complete LoPro gantry systems. The gantry bracket allows numerous gantry configurations to be built by offering flexibility in the types of LoPro systems that can be assembled together and in the relative positions and orientations of the stages to each other in the assembly. Procedures for creating the most common stage configurations for gantry systems can be found in the LoPro Gantry System Assembly Manual.

Custom Options

From adding mounting holes to completely custom systems, our application engineers are ready to assist you with any customization need.

Technical Guide

Download Support Literature

7TH AXIS FOR ROBOTIC SANDING

Complete Robot Transfer Solution Enables Highly Reliable Automated Sanding Through Resistance to Wear and Debris

THE CHALLENGE:

GrayMatter’s Scan&Sand™ system needed to consistently produce superior results while sanding variable workpieces. GrayMatter developed self-programming algorithms to instantly scan and compute the best possible sanding solution for the desired part. Their software then guides robotic arms which sand each part with superhuman quality and consistency.

INDUSTRY: Manufacturing - Robotics

PRODUCT USED: LoPro Linear Actuator, LoPro Gantry Kits

ROBOTIC EXCAVATION SYSTEM

Multi-axis Guides Help Keep Infrastructure Repair Process Clean & Controlled

THE CHALLENGE:

The RRES aims to reduce the exposure of contaminants to operators and the disruption to public spaces. This includes controlling debris produced by excavation. To maximize the benefit of their patented vacuum technology, ULC Technologies required an enclosure system that only allowed debris to exit through the excavation head while providing sufficient range of motion to the head.

INDUSTRY: Construction Equipment

PRODUCT USED: LoPro Linear Actuator, LoPro Gantry Kits

HYBRID ACTUATOR DESIGN

Custom Designed Actuator Provides Increased Stability for Heavy Loads

THE CHALLENGE:

To orient the products from the conveyor into finished bundles, the TPA was equipped with an overhead rotary end-of-arm mechanism that can shift in weight and speed based on need. However, this end-of-arm would become unstable and wobble at high speeds and heavier weights.

INDUSTRY: Packaging

PRODUCT USED: LoPro Linear Actuator, UtiliTrak

CNC PLASMA CUTTER

Actuator Gantry Beats the Heat and Debris

THE CHALLENGE:

The CNC plasma cutter operates on a manufacturing factory floor to produce parts from metal plates of various thicknesses. A fume extractor moves with the torch head to minimize the amount of toxic fumes that escape into the surrounding environment.

INDUSTRY: Cutting

PRODUCT USED: LoPro Linear Actuator

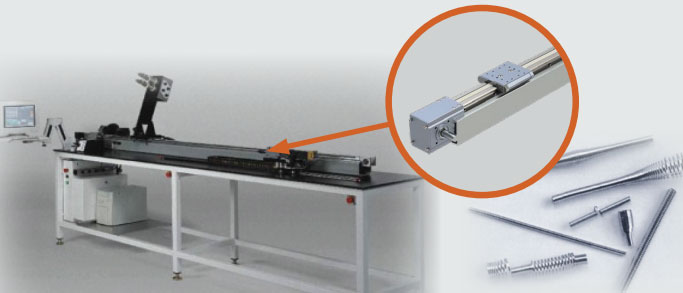

COIL-WINDING AUTOMATION

Smooth Motion Over Long Lengths for Medical Equipment Manufacturing

THE CHALLENGE:

The medical industry was in need of a coil winder that could mass produce wound wire products yet, at the same time, meet the demand for extremely high-quality coils. These coils are used in various applications, including as tools to implant stents and other medical devices into the body and as leads in pacemakers.

INDUSTRY: Medical

PRODUCT USED: LoPro Linear Actuator

52' BELT ACTUATED LOPRO

Guide System

Chain-Driven Linear Guide

Custom Linear Guides

Collaborative Robotics

Reliable Manufacturing Automation

Custom Actuated Linear Guides

High Quality Actuators