ECO60™ Linear Actuators

• Travel lengths from 3" to 36"

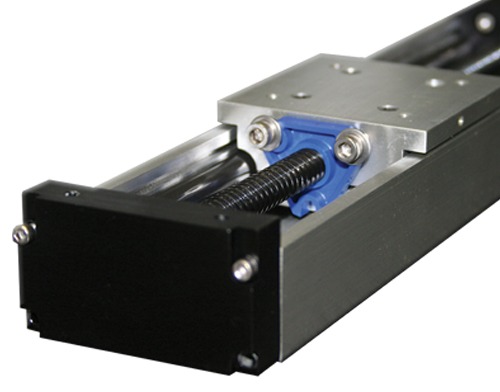

• Stainless steel lead screws with choice of lead

• Supplied with NEMA 17 motor mount flange

• Optional home and travel limit sensors

• Available in QuickShip

- Product Info

- Success Stories

- Faqs

- Reviews

There is newer and improved version of this product available HERE.

Overview

The ECO60 is a low cost, US made linear actuator in a small compact design that incorporates the latest in sliding element linear bearings and Bishop-Wisecarver prepared Mil standard Hardcoat aluminum shafting for smooth, and durable linear actuation. It includes an aluminum carriage with fully adjustable preload, and easy to replace sliding bearings. The aluminum construction and sliding element bearings make the ECO60 ideal for use in harsh or wet conditions.

Select ECO60 products are now available as part of the QuickShip Program.

Low Maintenance, Adaptable & Half the Price

The ECO60 is comparable to Asian actuators with a footprint of 60mm wide by 33mm tall. That’s where the similarities end. The ECO60 has a pre-loadable carriage top can be custom adjusted to suit your needs. Find the perfect balance between snug fit and smooth linear motion. As the sliding elements wear, make adjustments to correct until they are worn out and then replace them with an ECO60 repair kit.

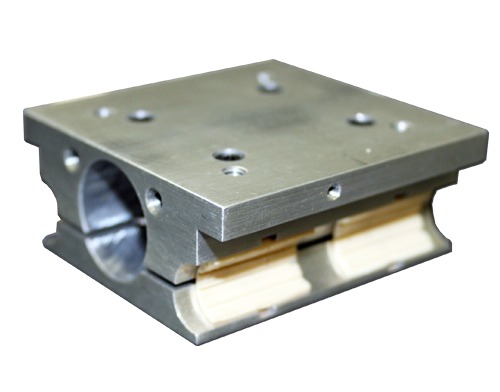

The ECO60 Carriage

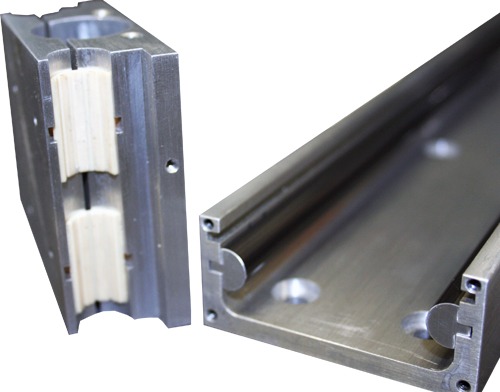

The ECO60 carriage is made from billet aluminum and all surfaces are machined to allow for correct contact and conformity between the sliding element linear bearings and the hard anodized shafting to enable smooth and efficient linear motion. The carriage is anodized and has stainless steel threaded inserts in the carriage pre-load adjusting threaded holes for improved durability and strength.

The ECO60 carriage is made from billet aluminum and all surfaces are machined to allow for correct contact and conformity between the sliding element linear bearings and the hard anodized shafting to enable smooth and efficient linear motion. The carriage is anodized and has stainless steel threaded inserts in the carriage pre-load adjusting threaded holes for improved durability and strength. The sliding element linear bearings are constrained inside specially machined notches to maintain alignment and make assembly simple. The liner bearing material is polymer and suitable for a wide range of applications including in wet and debris contaminated areas. The carriage pre-load is easily field adjustable to provide user preferred snugness and can be re-adjusted to compensate for wear on the linear bearings. The sliding elements can be replaced when worn out.

The ECO60 Repair Kit

BWC Offers a repair kit which includes the end support bearings, lead screw nut, sliding elements, bearings and a lubrication pen. The repair kit enable long service life without having to change the complete actuator assembly and within minutes you will be fully functional.

Harsh Environment Ready

Hardcoat shafting combined with the sliding linear elements make the ECO60 ideal for harsh or wet conditions including diluted lye, weak acids, cleaning agents for wash down applications, alcohol, hydrocarbons, grease, oils and fuel.

Durable Design

The ECO60 is made to be tough and durable. The base, end plates and top carriage are all made from 6061-T6 aluminum and are machined to have all surfaces within .002”. All parts are anodized for an attractive, corrosion-resistant finish. Linear slide shafting is made from hardcoat finished aluminum.

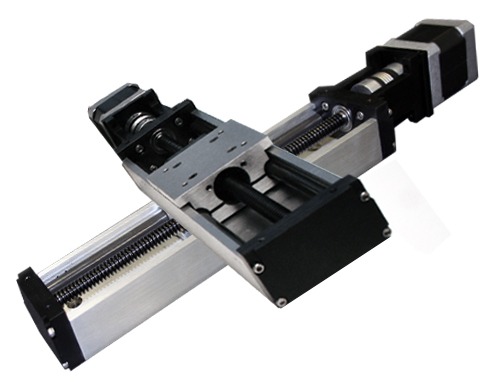

The ECO60 is made to be tough and durable. The base, end plates and top carriage are all made from 6061-T6 aluminum and are machined to have all surfaces within .002”. All parts are anodized for an attractive, corrosion-resistant finish. Linear slide shafting is made from hardcoat finished aluminum. Gantry Configurations

Gantry and multi-axis configurtions are simple to configure and design with the standardized gantry plates. The XY plate enables 2-axis attachment across a horizontal plane, while the XZ bracket enables 2-axis attachment in a vertical plane. The Signature Motion ECO60 can be mounted horizontally,vertically, or inverted without a reduction in load capacity.

Gantry and multi-axis configurtions are simple to configure and design with the standardized gantry plates. The XY plate enables 2-axis attachment across a horizontal plane, while the XZ bracket enables 2-axis attachment in a vertical plane. The Signature Motion ECO60 can be mounted horizontally,vertically, or inverted without a reduction in load capacity.Options

• Optional dust cover strip

• Home and limit travel sensors

• Lead screw pitch choices

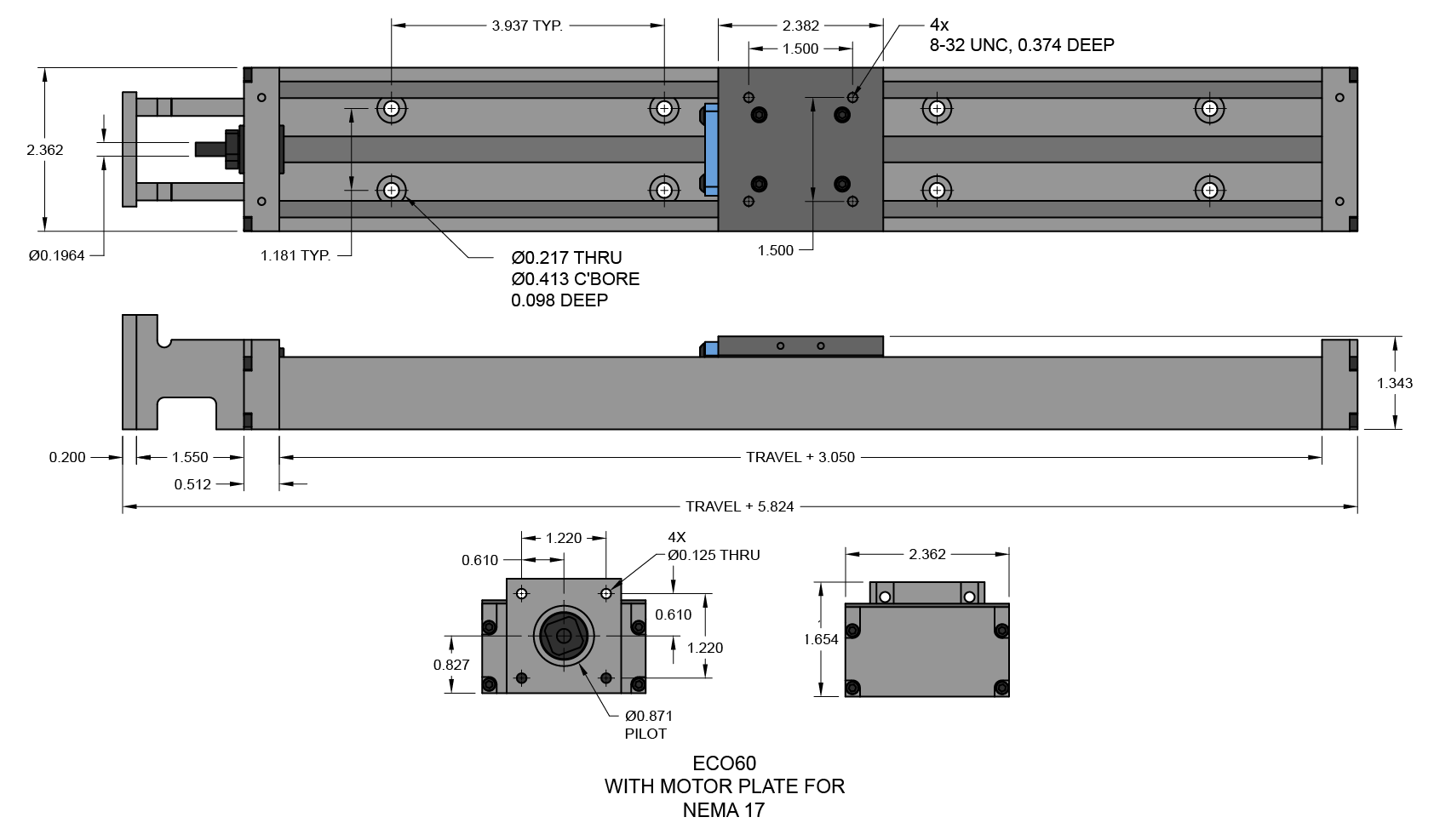

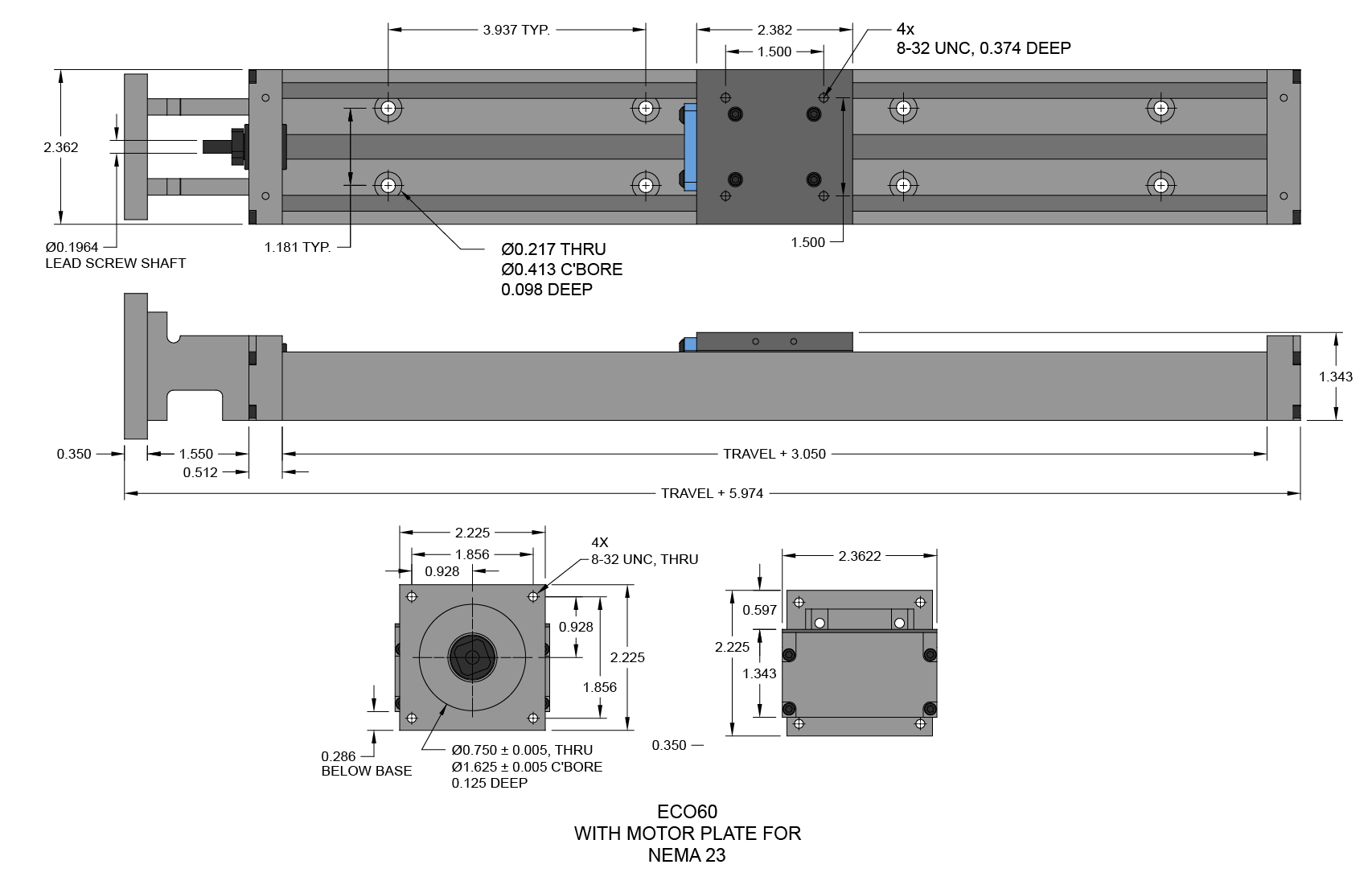

• NEMA 17 or NEMA 23 stepper motor mounts

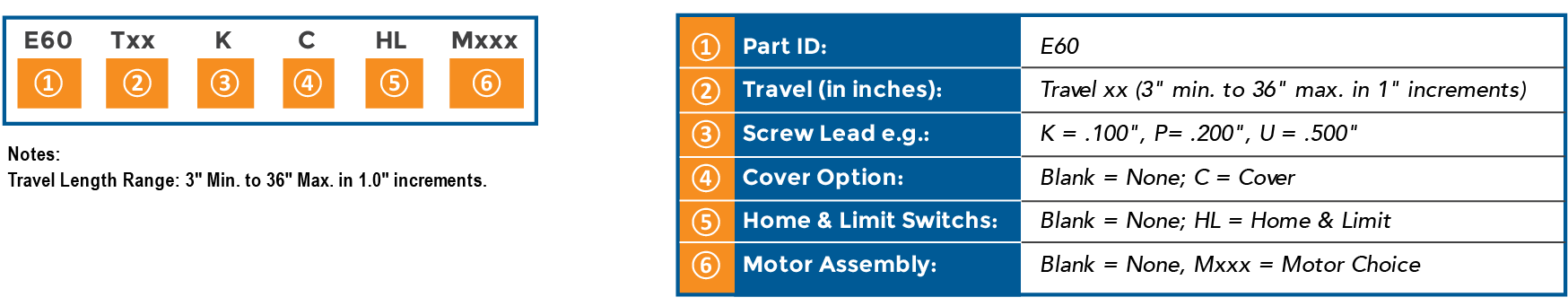

Product Numbering Scheme

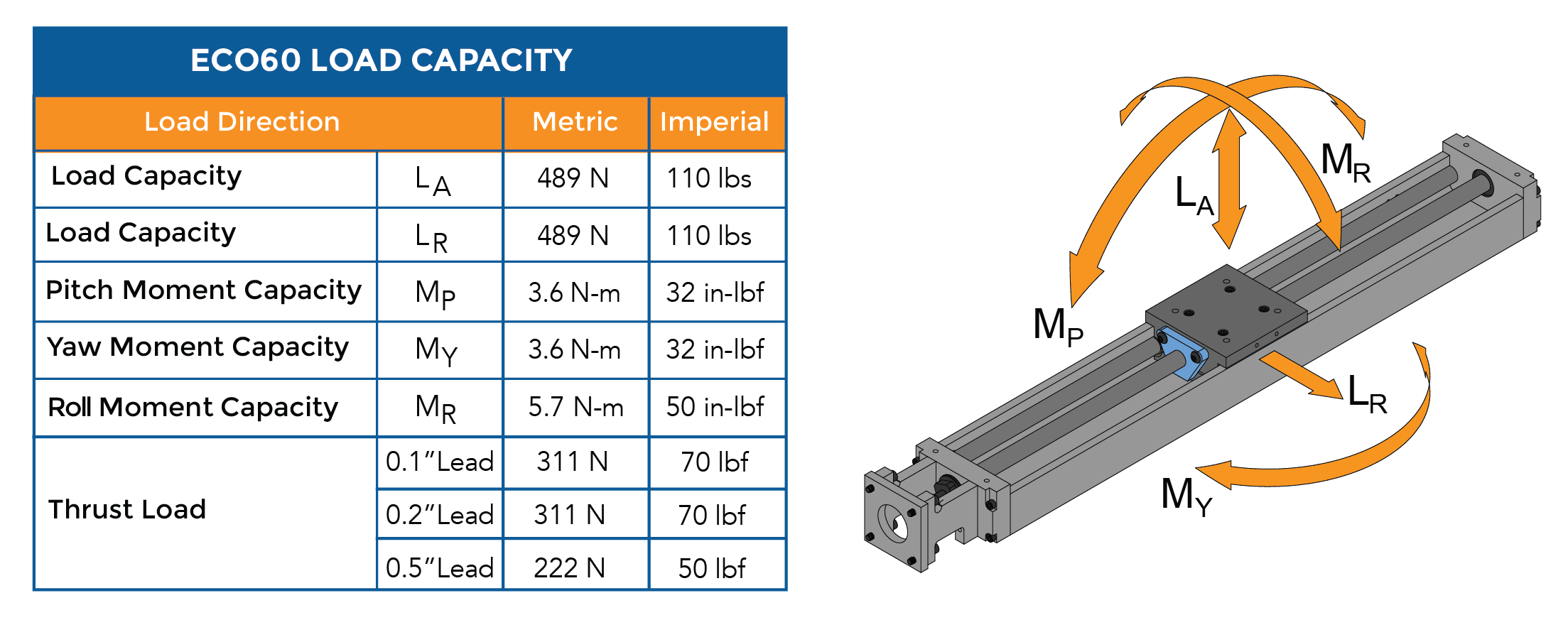

Load Capacity Ratings

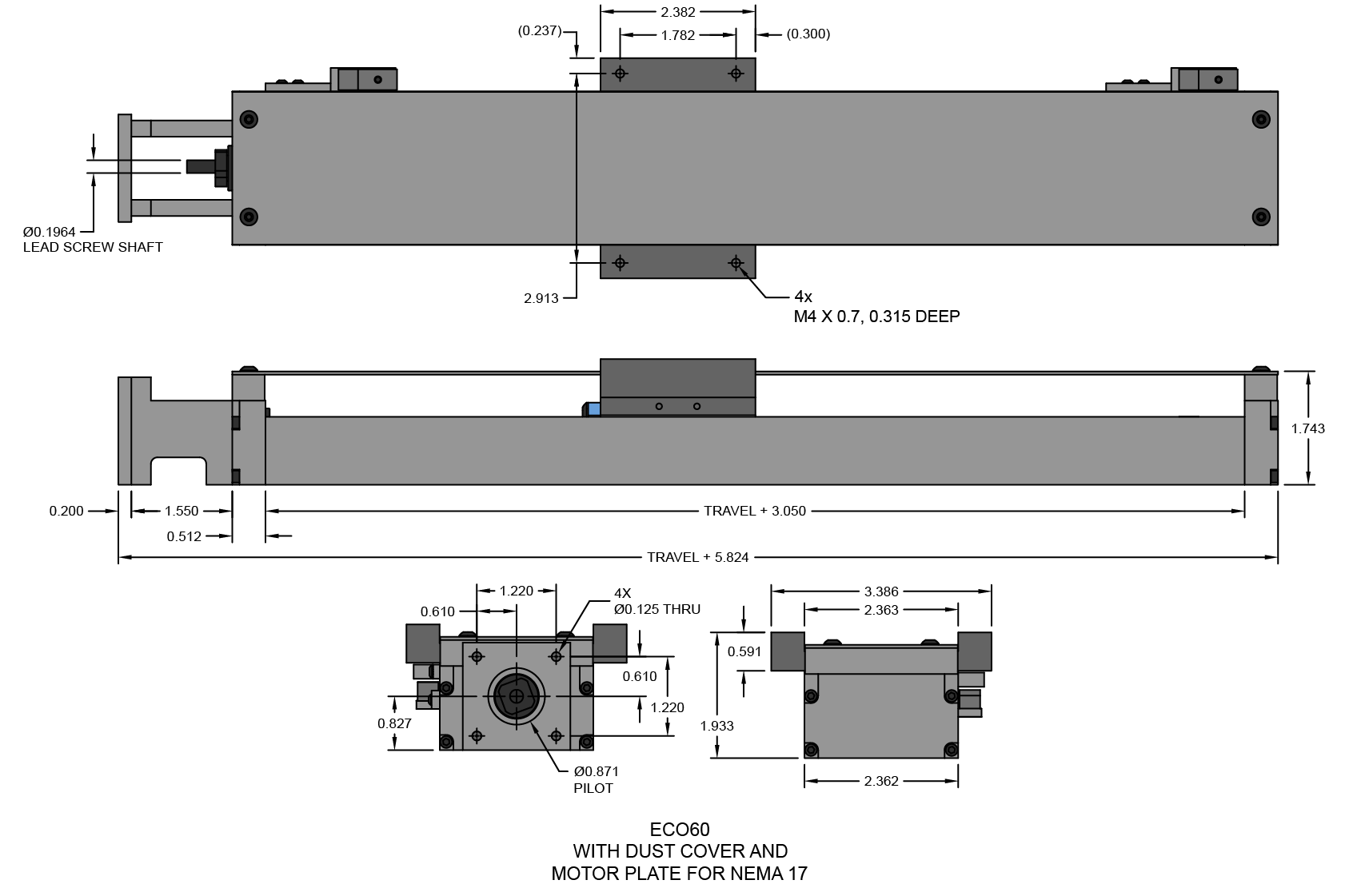

Dimensional Drawings

There is newer and improved version of this product available HERE.

Where are ECO60 actuator products manufactured?

ECO60 actuators are produced at BWC headquarters near San Francisco, California, USA.

What materials are ECO60 actuators made from?

ECO60 is mostly aluminum in construction and made from 6061-T6 and 6063-T6 grades. The fastener hardware is all stainless steel including the lead screw and support bearings. The lead screw nut and sliding element linear bearings are made of plastic polymers.

Why is the carriage preload adjustment feature a benefit?

The ability to adjust the carriage preload is a benefit to end-users because it enables an application specific "feel" or "tune". The adjustment can be loose for elss friction and lower wear rates, but a decrease in accuracy with additional carriage rock. A tighter adjustment will have more friction and higher wear rates, but improved accuracy and reduced carriage rock. Adjustments can be made periodically during the life of the actuator to compensate for wear in the bearing elements.

How much additional protection does the dust cover option provide?

The dust cover provides protection from debris falling onto the ECO60 from above. The sides remain open and exposed because of the design of the moving carriage. The dust cover is not effective when the actuator is mounted on the side. The cover does not have an ingress protection rating (IP rating), but if it did, it would be around an IP10 or IP20.

What fasteners are recommended for mounting ECO60?

The base of ECO60 has through hole and counter bore features to accomodate either 10-32 or M5 fasteners. Low head cap screws or button head cap screws in stainless steel are recommended.

How do I replace worn parts, or disassemble my ECO60?

There is a guide for how to properly disassemble an ECO60 and install the replacement parts that are provided in the repair kit. Contact BWC application engineers for this documentation.

How can I determine if ECO60 will work for my application?

Contact BWC application engineers for free technical advice on your application.